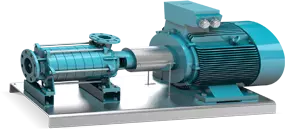

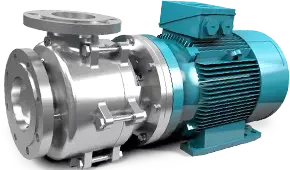

- Radial Pumps

- Regenerative Turbine

Pumps

since 1927

About the EDUR-Pumpenfabrik in Germany

About EDUR

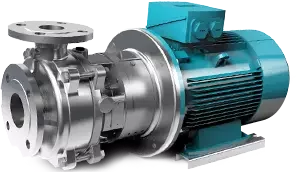

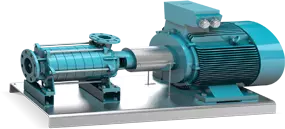

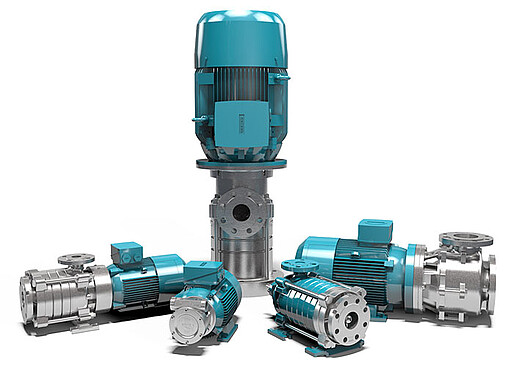

The pump manufacturer EDUR produces centrifugal pumps with high demand on quality and latest technology since 1927. The company offers individual solutions on high technical level for our customers in industrial engineering, oil and gas industry, air conditioning and cooling industry, surface technology and other markets. They produce selfpriming and non-selfpriming centrifugal pumps for handling liquids, multiphase pumps for liquids containing gas and for gas enrichment, torque-flow pumps for liquids with solids and special solutions for many different markets.

EDUR is represented worldwide and exports to all countries either directly or by local representatives and distributors.

Technologies

Our product range

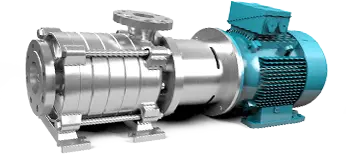

- Radial Pumps

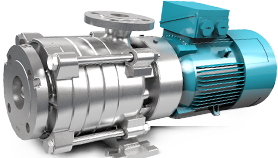

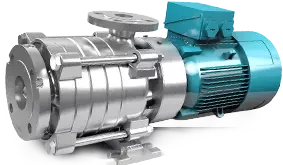

- Regenerative Turbine Pumps

- Multiphase Pumps

- Submersible Pumps (just immersed)

Contact EDUR

Company Contact:

EDUR-Pumpenfabrik Eduard Redlien GmbH & Co. KG

Edisonstraße 33

24145 Kiel

Germany

Fon: +49 431 68 98 -68

Fax: +49 431 68 98 – 800

Mail: info(at)edur.de

Web: www.edur.com