Multiphase Pumps for innovative Hydrogen Technologies

With the adoption of the National Hydrogen Strategy (NWS), the German government has opened up the opportunity for the German mechanical and plant engineering industry to become a global pioneer in the development of modern energy systems. The pump technology used is a matter of some significance in production, storage and use of hydrogen. However, the German pump manufacturer EDUR has already found a suitable solution.

The National Hydrogen Strategy (NWS) recently adopted by the German Federal Government is currently on everyone’s lips. This is an indispensable step towards energy system transformation and offers great potential for the German industry to maintain its strong “Made in Germany” position globally and to expand it by playing a major role in the development of these future technologies. According to the German government’s target, German greenhouse gas emissions are to be reduced by 80 to 95 percent by 2050. Green hydrogen for clean energy supply is becoming the central key component of the National Hydrogen Strategy: it is produced in a climate-neutral way on the base of renewable energies, e.g. through electrolysis.

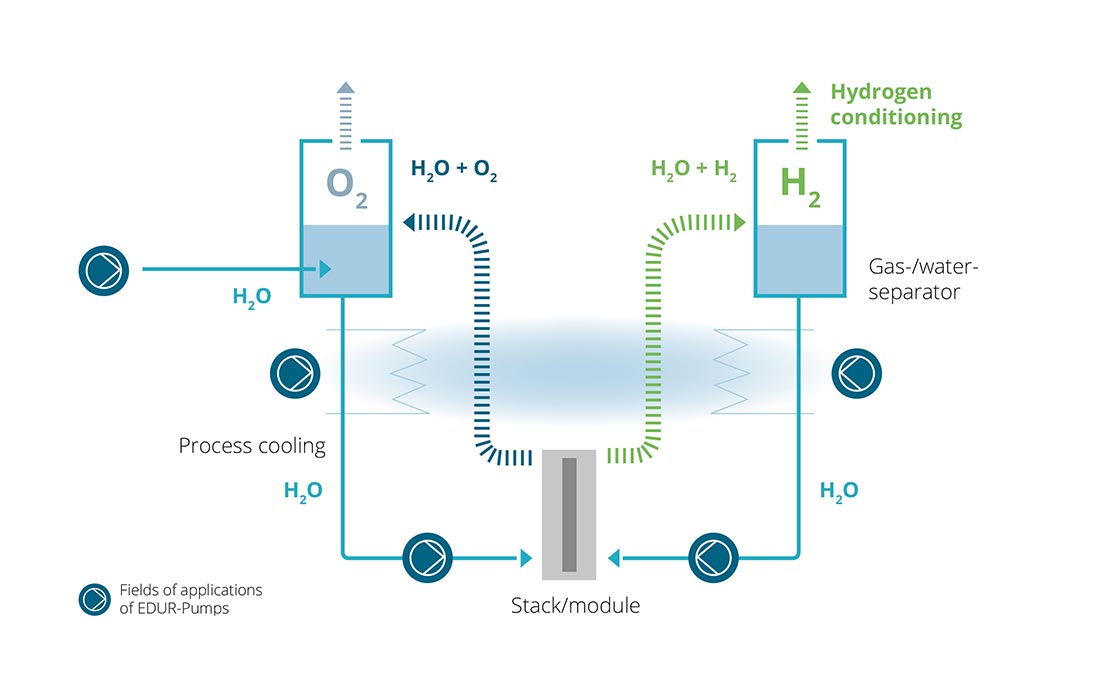

The rapid development of modern energy systems also places new demands on the pump technology used. In the production, storage and use of hydrogen, EDUR-centrifugal pumps offer some decisive product advantages that ensure reliable and efficient operation of the plants. In particular, the possibility of gas enrichment of liquids as well as the safe delivery of gas saturated liquids with the help of multiphase pumps holds great potential in the planning and development of modern energy systems. Other applications in the field of power to gas, such as methanisation, also use the advantages of multiphase pumps to dissolve hydrogen, for example.

To obtain hydrogen by electrolysis EDUR-pumps can be used in both alkaline and PEM electrolysis. After gas separation, they convey the still saturated medium safely back to the stack by heat exchangers, where it is loaded with free gas again. Possible shares of residual gas or outgassing resulting from the pressure reduction in front of the pump are safely controlled and conveyed.

The main advantages of EDUR-centrifugal pumps, apart from the gas conveying properties, are the low NPSH values and the high energy efficiency, e.g. through the use of lossless containment shells when using magnetic couplings. Furthermore, radial forces in the pumps are balanced by the ring housing used. Additionally, the EDUR-typical open impellers do not transmit axial forces to the shaft, so that the bearing in the magnetic coupling is only slightly loaded. Upon customer request, the pumps are designed according to ATEX.

There is no standard pump solution with EDUR. Every single pump is individually selected, planned and subsequently manufactured according to the application and requirements. EDUR thus offers planners, designers and operators of modern energy storage systems unique pump solutions, optimally designed for their needs.

Well-known manufacturers of electrolysers already rely on EDUR-pump technology. The pumps from Northern Germany, for example, are already being used successfully in some serial production plants. The electrolyzers are partially pressureless, but the trend is towards higher system pressures to reduce the post-compression of the gas. In whatever direction the technology will develop in the future: EDUR offers the right pump solution for both process requirements.

Source & Pictures: EDUR