Axial pumps are used for the promotion of incompressible fluids and are employed for large volume flows at relatively low delivery heads. As with all types of centrifugal pumps, the energy transmission in axial flow pumps is carried out exclusively through flow-related processes.

Axial Pumps

Technische Daten & Charakteristiken:

- Delivery rate: 2,200 – 3,100 m³/h (9,686 – 13,648 gpm)

- Delivery head: 5.9 – 10.5 m (19.4 – 34.4 ft)

- Pressure: 0.6 – 1.1 bar (8.7 – 16 psi)

- Viscosity: up to 150 cP

- Temperature: -5 till 60 °C (23 till 140 °C)

- pH-value: 2 – 14

- Gases: up to 10 %

- Solids: up to 0.02 % (max. 10 mm)

- Installation: horizontal

- hygienic desing possible

- Drive: Elektro

Working principle of Axial Pumps

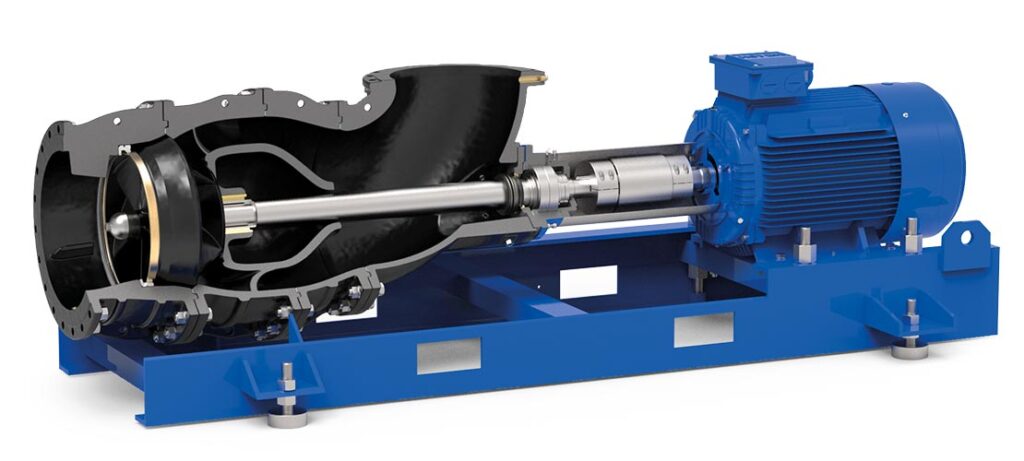

Axial flow pumps are centrifugal pumps in which the fluid is pumped parallel to the pump shaft.

The flow mechanism in a centrifugal pump can generally be described as follows: Through a suction flange the liquid flows through the suction hub into the rotating impeller due to an energy fall. The pump unit absorbs mechanical energy from a drive motor through a shaft. The blades of the impeller which is permanently fixed on the shaft exert a force on the fluid and increase its angular moment. Pressure and absolute speed increase as a result. Consequently energy is being transferred to the fluid. The energy which is present in kinetic form as an increased absolute speed is usually converted into additional static pressure energy by a diffuser device. Nowadays volute casings or bladed diffusors normally are being used as diffuser devices. In combination with the impeller the diffuser device represents the so-called hydraulic of the pump. To maintain the flow there also has to be an energy fall directly behind the pump after the outlet from the discharge flange, analogous to the pump inlet. Losses occurring in the system for example due to friction or leakage flows require an increased power consumption of the pump.

Axial flow pumps differ in their constructive and functional characteristics due to their pre-determined installation location and the liquid to be pumped. For pumps of one model range various installation types may be implemented. The hydraulic characteristics and the pumping performance remain nearly unchanged. Main characteristics are the design of the shaft in the horizontal or vertical position, the position of the pump connections and the connection type of the pump to the drive unit using a coupling or direct assembly on the motor shaft (block design).

Range of applications of axial pumps

Axial flow pumps are used for large volume flows and small delivery heads.

Typical areas of application are:

- Irrigation

- Sewage Treatment Plants

- Cooling Water Pumps

- Drainage Systems

- large Water Parks

Technical features of a axial pump

- compact design

- direct drive without gearbox (compared to numerous positive displacement pumps / also a benefit regarding efficiency and complexity, repair, maintenance,…)

- dry installation, immersed or submerged

- sealing systems / hermetically with magnetic coupling