A centrifugal pump whose impeller rotates in a concentric channel – this is the special feature of the peripheral pump (alternative term: regenerative turbine pump). The pressure of the fluid handled increases from the inlet to the outlet thanks to this design. Even with their relatively small casing, the pumps therefore offer a great energy increase. That’s why peripheral pumps are especially well-suited for small pump capacities with high pressure.

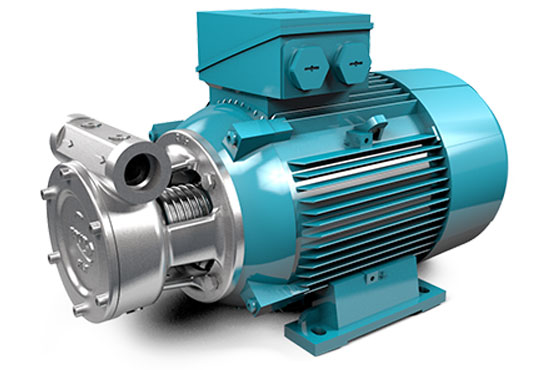

Peripheral Pumps

Technical Data & Characteristics:

- Delivery rate: 0.1 – 17 m³/h (0.4- 75 gpm)

- Delivery head: up to 400 m (1,312 ft)

- Temperature: -60 °C to 300 °C (-76 °F to 572 °F)

- Pressure: up to 40 bar (580 psi / 4 MPa)

- Viscosity: up to 115 cSt

- pH-value: 0 – 14

- Gases: up to 50 %

- Installation: horizontal

- sealless design possible at some series

- Materials: stainless steel, duplex, Ni-based, austenitic steel, spheroidal graphite iron

- ATEX: suitable for ExZones 1 & 2

- Drives: electro, hydraulic

- Variants: bearing bracket, block design

The peripheral pump is part of the large group of centrifugal pumps. Its design is similar to that of a side channel pump: The impeller consists of a disk with straight vanes on its periphery. Normally, each of the impellers has more than 20 vanes, which are arranged in star shapes on both sides of a carrier hub.

The fluid handled is pumped through a ring channel: A peripheral space between the impeller and casing wall. Due to the rotation of the impeller, the kinetic energy is transferred to the fluid handled. In contrast to side channel pumps, the side channel of a peripheral pump also extends along the front side of the impeller.

The centrifugal forces inside the pump mean that the fluid handled is recirculated from the ring channel back into the impeller multiple times. This increases the energy transfer and large heads can be achieved despite the pump’s small size.

A narrowing of the casing between the inlet and outlet causes a pressure difference: The pressure increases in the course of the pumping process. Users can make use of this property if a pressure increase is desired during handling.

In addition to their compact size, some peripheral pumps are self-priming. In any case, the technology offers high tolerances with regard to gas content in the fluid handled. Even with an outgassing of the medium or a brief intake of air, peripheral pumps can work without interrupting the flow rate.

If fluid-gas mixtures are handled, these pumps can be used to generate stable micro-bubbles. A direct gas addition in accordance with VDMA24430 is also possible.

Due to their construction, peripheral pumps provide low axial thrust, so that fewer measures have to be taken for compensation. With their linear decreasing characteristic with increasing flow rate, they are easy to manage and are used especially to handle small flow rates.

In this special design, a stage with a suction impeller is installed upstream. Thanks to this and the axial inlet, low NPSH requirements are achieved; ideal for applications with low capacity/minimum flow and high head, also known as low flow – high head applications. This kind of peripheral pump stands when it comes to pressure. Thanks to its heavy-duty design it is capable of an operation pressure of 40 bar (580 psi). Therefore, it is possible to cover a wide range of applications due to configuration options in terms of stages and hydraulics. With the magnetic coupling, this pump type meets the highest safety standards as it is leakage-free.

Peripheral pumps are used when large heads with low flow rates are required. Furthermore, these units score points in applications where small pumps are advantageous, for compact pumps require smaller measurements for the same pump output as compared to other pump technologies.

This technology is suitable for pure, non-abrasive, and soiled fluids. It can be used, among other places, in the chemical industry or in mechanical engineering for cooling, recirculation, and as a small boiler feed pump, but also to increase pressure in water networks and car wash systems.

For applications in industry, peripheral pumps are also used to enrich and mix fluids with gases. Main areas of application are:

- Biofuel systems

- Dissolved air flotation

- Neutralization

- Drinking water purification

- Bioreactors

- Raw oil-water separation on drilling rigs and in oil fields

- General process engineering

The capability to handle fluids with high gas content, their appropriately high tolerance with regard to cavitation, their linear characteristic, and compact size make peripheral pumps popular specialists for particular applications. However, this does not mean that peripheral pumps are only used in exceptional cases: Their specific properties make them the de facto standard in certain areas of the chemical and petrochemical industries.

As multi-stage pumps with up to three impellers, the peripheral pump can achieve heads of up to 1,200 meters. Thanks to such properties, these pumps can even exceed the performance of displacement pumps in particular areas of application.