The side channel pump is a specialist in particular areas of application that occupy the niche between centrifugal pumps and positive displacement pumps. These pumps offer many benefits: They are self-priming, not sensitive to cavitation, they can easily handle fluids with high gas content, and they are suitable for pressure-dependent circulation regulation. Generally, side channel pumps are especially good for “low flow – high head” applications.

Side Channel Pumps

Technical Data & Characteristics:

- Delivery rate: 0.3 m³/h up to 42 m³/h (1.3 – 185 gpm)

- Delivery head: up to 1200 m (3937 ft)

- Pressures: up to 110 bar (1595 psi)

- Temperatures: – 60 °C to + 220 °C (- 76 °F to +428 °F)

- Viscosity: 0,1 mPas to 230 mPas

- pH-value: 0 – 14

- Gases: up to 50 %

- Solids: up to 0,1 % (max. 0,1 mm)

- Installations: horizontal, vertical

- Depth: up to 10 m (33 ft)

- self-priming

- sealless design possible

- ATEX: suitable for ExZones 2 & 1

- API, ISO, EN standard

- Drives: electro, diesel, hydraulic

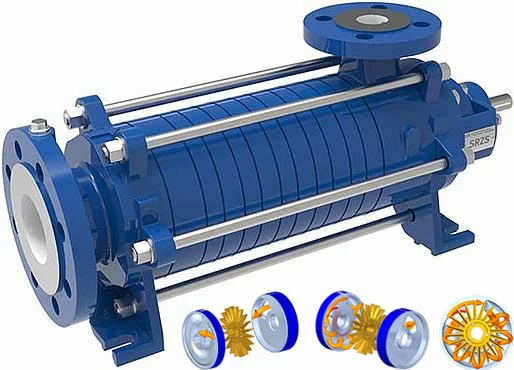

Self-priming, rotating side channel pumps transfer their power from a multi-stage star wheel, which rotates concentrically in the pump housing, to the fluid handled, which is in a side channel next to the impeller. The rotary movement of the star-shaped impeller and the centrifugal effect thus created cause the fluid handled to circulate multiple times between the cells of the impeller and the side channel of the pump, while the rotation of the impeller superimposes a circular flow direction.

This creates flow lines in the form of a circular ring helix on which the fluid handled moves. The fluid handled and impeller interact multiple times in the course of the handling process, which is why the energy transfer is especially powerful. This makes heads possible which, with the same circumferential speed, reach a multiple of the values of classic centrifugal pump impellers, especially with multi-stage side channel pumps.

The centrifugal effect in a side channel pump causes a temporary phase separation in the fluid handled: Gas components (also air) collect inside the impeller and are transported along to the gas outlet, where they are mixed with the fluid flow once again. While in the beginning, there is a displacement of the mixture handled (as with a positive displacement pump), the pump then switches to pure fluid handling. If it is completely filled with the fluid handled, the side channel pump effectively works as a centrifugal pump.

Side channel pumps are used to handle small quantities with medium to large heads. Since they can handle fluids with high gas content, they are often used for such media, for example to transport scalding media with low viscosity. Therefore, fluids with a gas content of up to 50% volume can be handled continuously with this type of pump.

Side channel pumps also offer very low NPSH values, which is why scalding media can be handled close to the vapor pressure curve. In contrast to other pump technologies, the flow rate does not break down even with partial outgassing or a brief air intake.

Examples of applications for side channel pumps:

- Fuels: Gasoline, diesel and biodiesel, methanol, autogas (LPG)

- Industrial refrigerants: Ammoniac, R-134A, CO2, DME, R-1234yf

- Propellant gases: Aerosols, foaming agents

- Volatile chemicals: Butadiene, propylene, styrol

- Aromatics and solvents: Xylol, toluol, isopropanol

- Hydrocarbons: Ethane, propane, butane, pentane

- Water: Drinking water, sea water, boiler feed water, steam condensate

Exotic with many benefits

Essentially, side channel pumps manage to combine many benefits of centrifugal pumps with beneficial properties of positive displacement pumps. They are self-priming, they offer inexpensive and safe suction piping and suction tanks, enable stable two-phase flow, and are especially well suited for use in systems with low NPSH values. Added to this is the already-mentioned possibility for handling fluids with high gas content up to 50 vol-%. It is also certified according to API and usable in the Ex zones 1 & 2.

Applications where large quantities of fluids have to be handled, by contrast, are not the best application for these pumps. But if small quantities have to be pumped with very high heads, side channel pumps are an excellent choice!

High performance with low operating costs

The design of a side channel pump is not as simple as that of a radial pump, but it is essentially easy and inexpensive to maintain and service. Usually, less expensive cast iron is used as the material. The low-speed drive of the units also has a positive effect on service life since the construction is spared excess wear. Nevertheless, side channel pumps offer a broad range of speeds.

Due to their steep, linear characteristic, side channel pumps can be regulated easily. They are suitable for high suction pressures of up to 35 bar, in high-pressure design up to 100 bar. Since the impellers rotate with values that can reach a multiple of normal pump impellers, side channel pumps can also be used to increase pressure in the system.