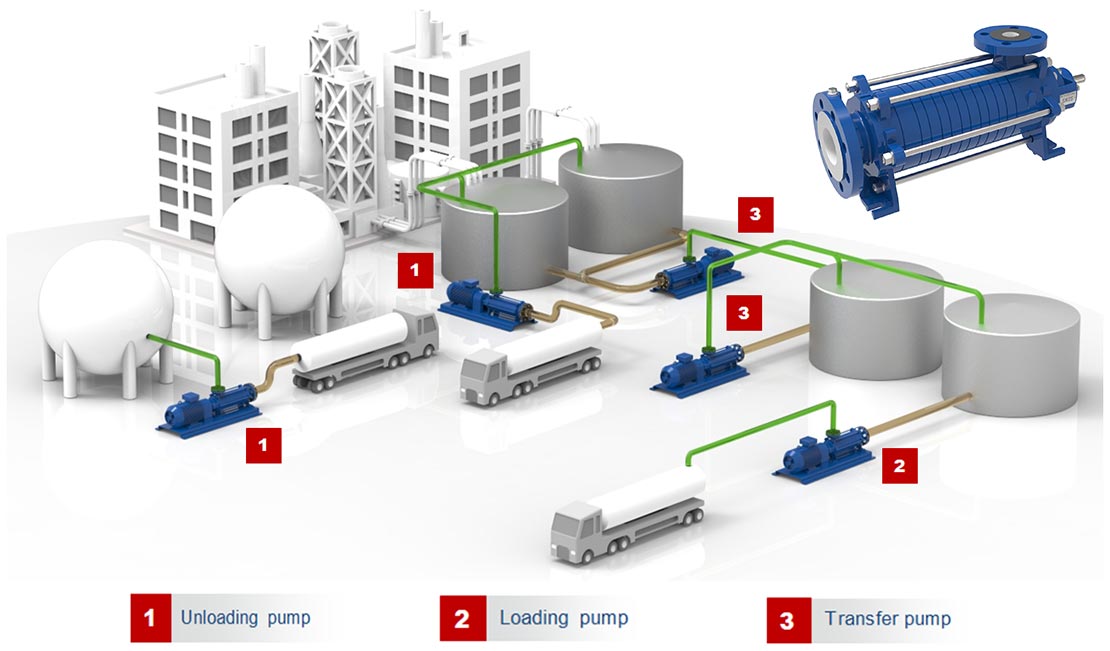

Side Channel Pumps in Tank Farms

Tank farms are installed in many chemical facilities to stock either raw materials or finished products. Equally, independent storage facilities are also common for interim storage, as found in numerous seaport terminals. The wide variety of stored liquids ranges from solvents, which are usually kept in relatively small tanks, to fuels and liquefied gases in large containers with a capacity of several thousand cubic meters. In each of the following three applications, side channel pumps are the first choice for tank loading and unloading.

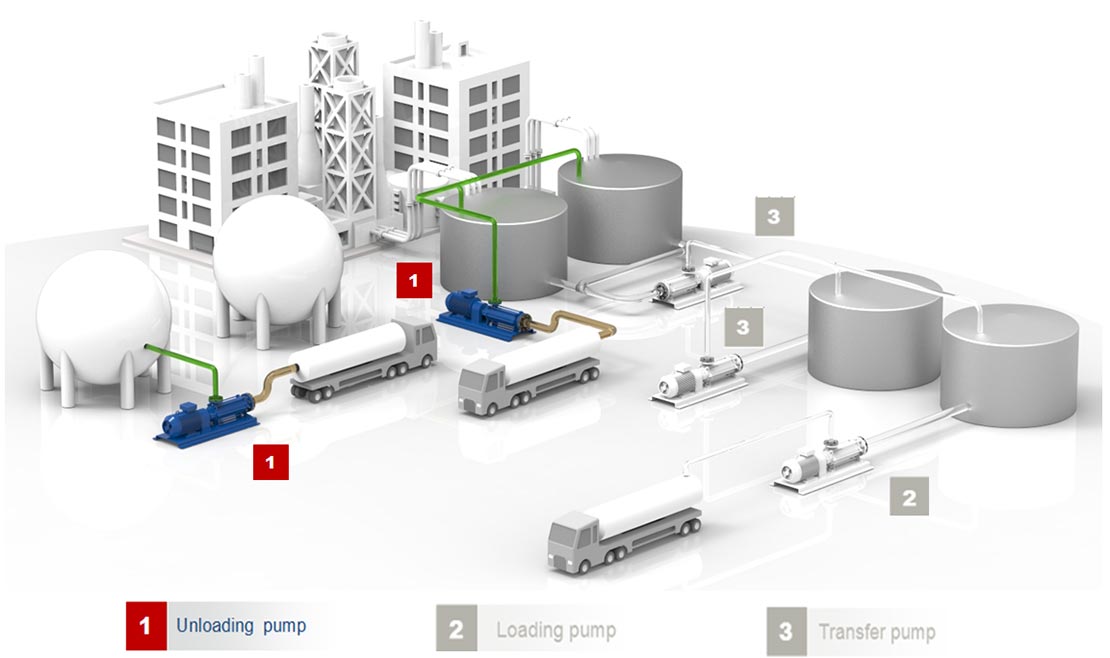

Application 1: Unloading

Unloading pumps are used for emptying road tank trucks, rail tanks or sea carriers and further transferring the liquid into tanks. The technical requirements placed on these pumps depend on the physical properties of the conveyed liquids e.g. acids, solvents or liquid gases. For this the pump series SVM, SEMA-S and SRZS of SERO can be used.

Benefits of the Side Channel Pump:

- Gas handling up to 50% without interruption of pump flow

- Depending on the unloading conditions: Extremely low inlet height / NPSH

- Self-priming capability of this pump design is vital, especially for “overhead” unloading from above

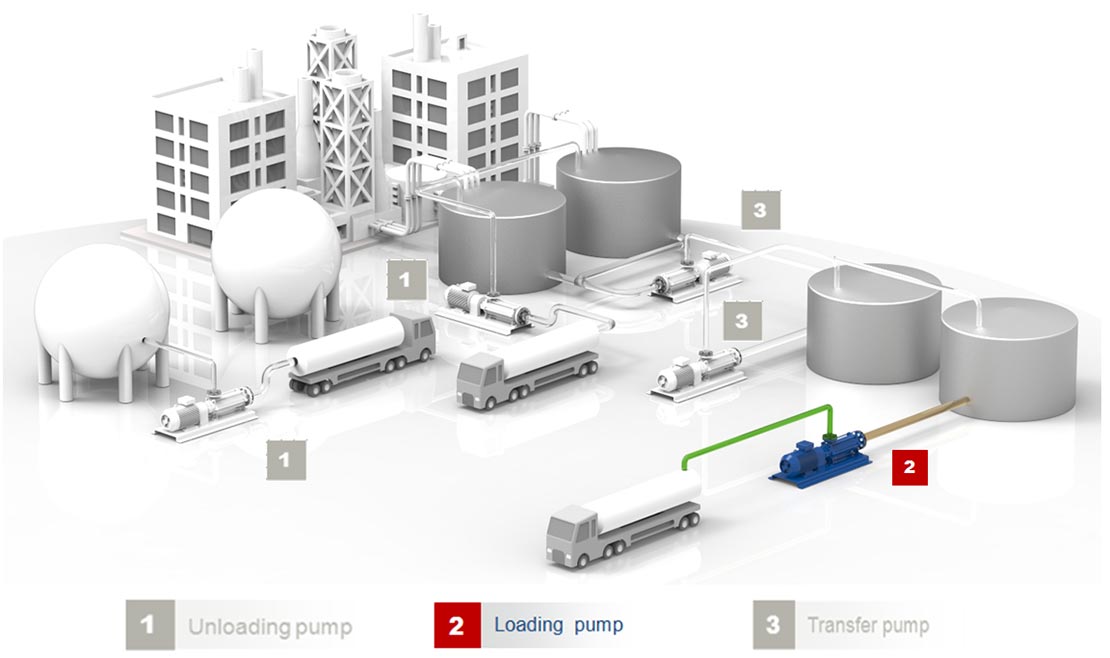

Application 2: Loading

The loading pumps are used to transfer the stored or produced liquids into road tank trucks, rail tanks or sea carriers for subsequent transport to any of the onward processing sites. Here too, the requirements placed on the pumps largely depend on the conveyed media and their physical properties. In particular, low-boiling liquids, such as liquefied gases, have special requirements with regard to the NPSHr value and the ability of the pump to handle gas or vapor bubbles.

The SERO side channel pumps of the series SRZ, SRZS and SVM can be used at this application for liquids like acids, solvents, liquid gases or lyes.

Benefits of the Side Channel Pump:

- Excellent self-priming capability

- Gas handling up to 50% without interruption of pump flow

- Quiet operation

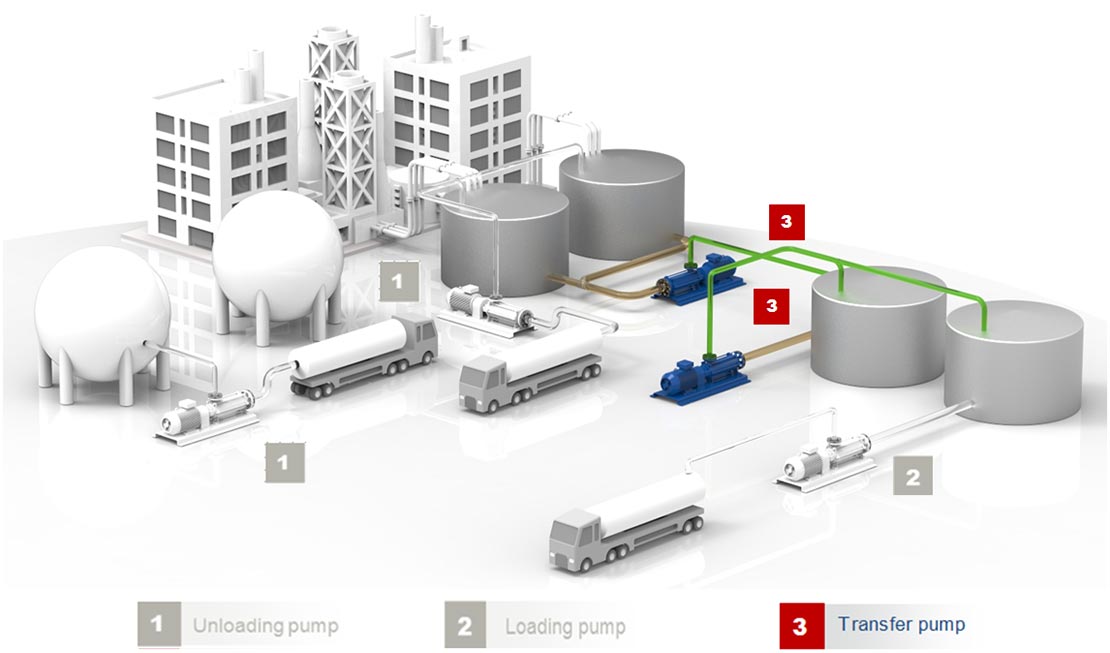

Application 3: Transfer

Transfer pumps are in many cases identical to loading pumps. The main difference is that these pumps are used to transfer the liquids to a plant for further processing of the substances and compounds. The flow rates are also lower. Depending on the requirements or characteristics of the further production process, these pumps have to overcome a larger differential pressure. That is why we recommend to install multistage pumps.

The SEMA-S or SVM series from SERO are suitable at this application to tansfer e.g. hydrogen peroxid, ammonia, liquid gases or different types solvents.

Benefits of the Side Channel Pump:

- Self-priming capability

- Steep characteristic curve with high differential pressure and at low flow

- Gas handling up to 50% without interruption of pump flow

Source & Graphics: SERO PumpSystems