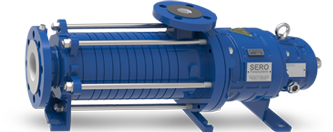

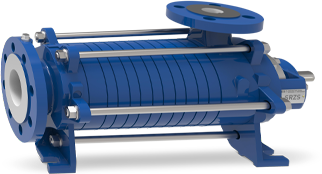

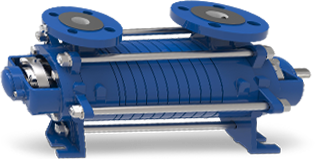

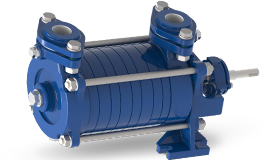

Side Channel Pumps

- low flow – high heads

- selfpriming

- gas handling

- extremely low

NPSH requirements

since 1894

SERO Imagefilm

About SERO

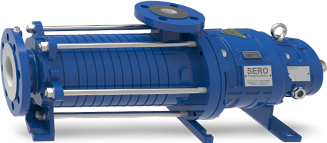

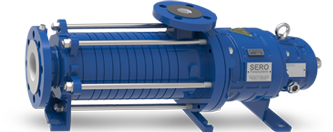

SERO PumpSystems GmbH is a family-owned German pump manufacturer. More than 80 years of experience as the only exclusive manufacturer of side channel pumps have made SERO a technology leader in this field, providing customized pump solutions for the efficient and safe transfer of liquids and liquid-gas mixtures. Customer service and sales are handled through a worldwide network of agents and own subsidiaries.

Technologies

Our product range

- Side Channel Pumps

- for chemicals

- for oil, gas & petrochemicals

- for marine / ship building

- for energy technic

- Hydrophore Systems

thanks to- low flow – high head

- selfpriming

- gas handling

- extremely low NPSH requirements

Contact SERO

Company Contact:

SERO PumpSystems GmbH

Industriestraße 31

74909 Meckesheim

Germany

Fon: +49 6226 9201-0

Fax: +49 6226 9201-55

Mail: info(at)seroweb.de

Web: www.seroweb.com

Personal Contact:

Mr. Klaus Reischl

Head of Sales / Sales Manager

Fon: +49 6226 9201-0

Mail: sales@seroweb.de