HP units including regulating choke, valves and controls for the pressure testing unit for hydraulic testing at H2 gas tanks by one provider

At any rate, a key function our units have to fulfil is both to run 1-10 full cycles per minute and to be able to release that pressure after ramping it up. Accordingly, that means that our pumps have to be operated in intervals or with swelling loads. Another unique challenge when strength testing for pump systems (including valves, regulating chokes, sensors and controls) is to precisely hit and control the desired pressure.

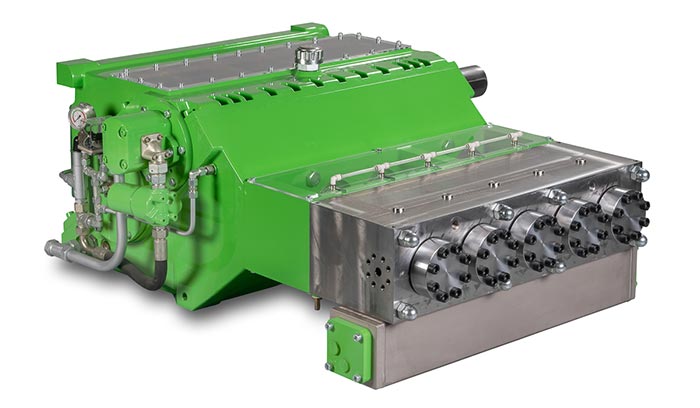

Due to the design of the KAMAT pump, upper pressures of up to 1350 bar can be achieved in this setup. This raises the question of how exactly the pumps can be pressure-controlled. A suitable solution was designed with the engineering department, including the necessary valve, control and automation technology. All of the parts needed are designed and manufactured in-house at KAMAT – All from one provider.