A strong team for metering tasks

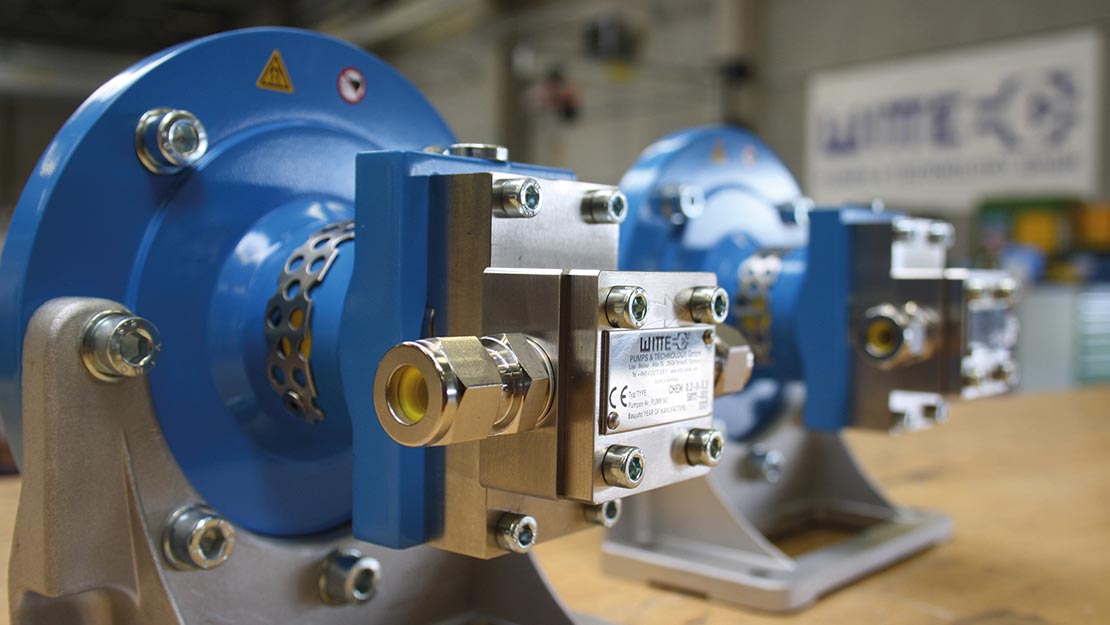

WITTE showed a wide range of innovations at Achema 2022. The product focus concentraded on the topic of metering. Among other things, we presented a dosing system with the new WITTE Core Command®controller unit and a new chemical pump.

The new gear pump is a metering pump for low-viscosity media for applications where high pressures and a wide temperature range are required. Another product highlight was a process design that is rather untypical for gear pumps in the form of a 2-stage pump system. This system is also very suitable for building up a comparatively high pressure with low-viscosity media.

However, there are not only innovations in the products themselves, but also the concept of the product name has been revised. In the future, all WITTE pumps will be known under new names. For example, the CHEM series will become the ChemCore® series.

However, nothing has changed for the customer in terms of design, equipment, and areas of application. The renaming was necessary to achieve better differentiation and to have the products protected under trademark law aspects. The addition “Core” also symbolises the importance of the pumps in the process. Pumps are the core and the heart of the system. Without them, production and the process come to a standstill.

WITTE Core Command®

The new WITTE Core Command® pump control serves as an extension of the WITTE gear pumps and can also be easily integrated into existing processes. The WITTE Core Command was developed together with a specialist for automation technology. This type of control is specially designed for use with WITTE gear pumps but can also be used with pumps from other manufacturers. More than 35 years of gear pump experience of the WITTE experts have gone into the development of this new control system.

The most modern components were installed in the control system according to the current industry standards. The control itself is based on a Siemens PLC S7. This ensures that in the event of a replacement only the software must be re-read without the need to completely reprogram the control. In case of a defect, the PLC can be exchanged quickly and easily.

The operation is carried out via a touch-sensitive 7-inch panel that offers sufficient space to read all necessary information at a glance and to carry out the parameterization comfortably via finger input. The control system is housed in a small control cabinet that complies with the current industry standard. Due to its small dimensions, it can be flexibly positioned in the immediate vicinity of the pump.

External components such as frequency converters, volume or mass flow meters are connected using the usual plug-in connections, which also comply with current industry standards. This ensures uncomplicated and seamless integration into existing process environments. During development, great importance was attached to high flexibility. In addition to standard interfaces such as Profinet, Ethernet or USB, optional interfaces are also available. If desired, the user can use CANBus, AS-Interface, Modbus or Devicenet™ connections here, as well as connect additional sensors.

On the software side, the control system has various operating modes such as batch operation, i.e. the delivery of a previously defined quantity, manual operation, i.e. a manual speed setting without control operation or control for flow via an external flow meter. For maximum accuracy, the system is self-learning, i.e. flow rates due to dripping or overrunning of the pump are detected and the shutdown of the pump in the next batch is optimised accordingly. Automatic data logging during operation gives the user full control and transparency over his batches. If deviations occur during operation, they can be precisely assigned to a batch based on the history. The batch can then be checked for any quality deviations.

In combination with the dosing pumps of the ChemCore® series, even demanding and complex metering tasks can now be realised with one system. WITTE offers metering systems and miniature systems from a single source. The systems can be selected in consultation with the customer so that a variety of components from different manufacturers can be chosen. Flow meters, drive units or sensors can be adapted to the customer’s needs.

The repeatability of the metering system is usually dependent on the components used, such as the flow meter. The finer and more precise the settings can be made here, the more precise the result can be set.

The new gear pump series: ChemCore®

The pumps of the ChemCore® series have been specially developed for the needs and applications in process engineering and the process industry. The pumping range covers a viscosity spectrum from 0.5 to 1,000,000 mPas. The pumps can be operated in a temperature range of up to 300°C in the standard version. On request, however, pumps can also be used in higher temperature ranges with the appropriate modifications.

Based on the WITTE modular system, the customer can choose from a variety of material combinations and sealing systems. In addition, different heating variants are available. The WITTE ChemCore® belongs to the group of chemical pumps. Designed accordingly, it can also be installed and operated in ATEX zones without any problems. The user-friendly design guarantees quick disassembly for maintenance and easy cleaning and inspection of the core components.

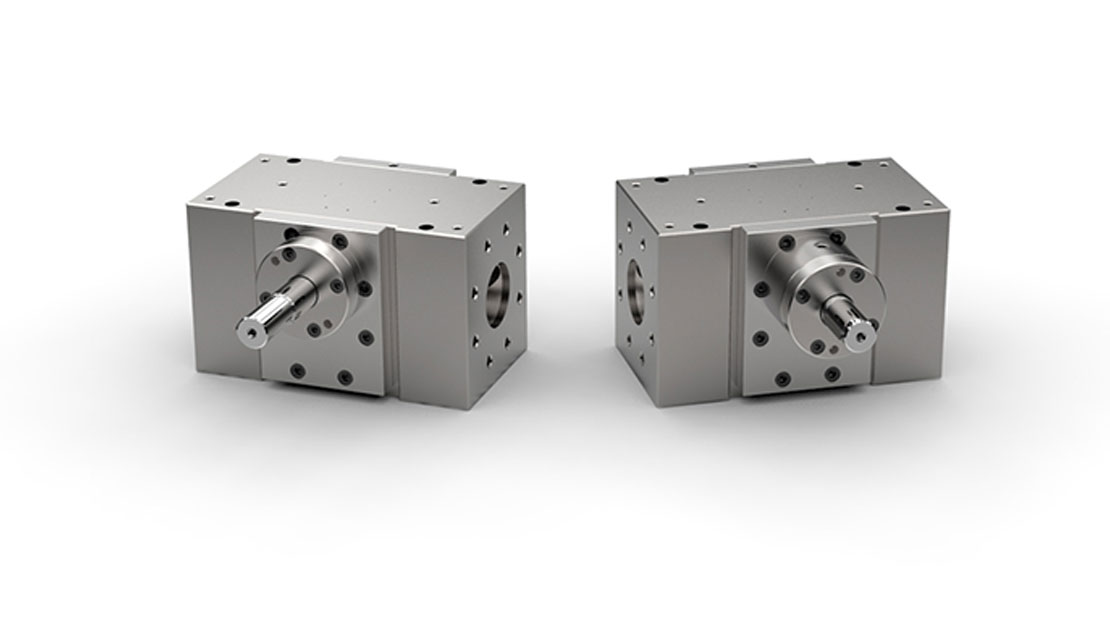

ChemCore® LZ – Drop-in-replacement for Hermetic gear pumps

The new ChemCore®-LZ series is a drop-in replacement for Hermetic-LZ gear pumps. WITTE PUMPS & TECHNOLOGY GmbH now offers all users and operators of Hermetic LZ gear pumps an alternative solution.

The LZ series, which was discontinued by Hermetic in 2018, is still in operation in many plants. However, replacement pumps from the original manufacturer are no longer available. Repair and spare parts supply for defective pumps or wear parts is no longer guaranteed by Hermetic. This is a field of application that WITTE PUMPS & TECHNOLOGY GmbH, with its more than 35 years of expertise in the gear pump business, has now taken on.

WITTE now offers all users and customers an alternative pump. In agreement and cooperation with HERMETIC, WITTE PUMPS & TECHNONOLGY GmbH will continue this series and take over the design and manufacture of the pumps under its own name ChemCore® LZ. The pumps offered under the new name are absolutely identical in terms of the connection dimensions but are equipped with internal parts from the WITTE modular system.

This means that the user can easily replace the pumps as drop-in replacements without having to modify the system and connections. The quality and grade of the pumps and components meet the WITTE standard. The ChemCore® LZ is available with a single mechanical seal, a double mechanical seal or a magnetic coupling and the matching coupling connection.

The advantage of this new series

The internal parts come from the in-house modular system for the established chemical pumps of the ChemCore® series. Gear shafts and friction bearings are identical to those of the WITTE chemical pumps. This brings another advantage for the customer in terms of spare parts stocking. In future, spare parts can be used for both pump types, provided the material pairing and size are identical. In the event of a replacement where a ChemCore® LZ is no longer to be used, WITTE also offers a modification of its own ChemCore® series. The company specialises in customised solutions for conveying tasks with gear pumps.

Source & Pictures: WITTE Pumps & Technology