Gear Pumps

- for chemicals

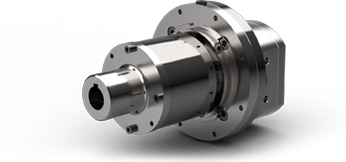

- for high-pressure

- for polymer processes

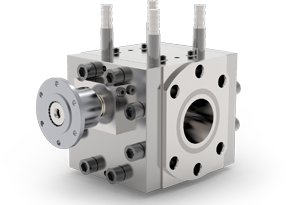

- for extrusion processes

WITTE PUMPS & TECHNOLOGY GmbH

About WITTE

As a market leader for gear pumps, WITTE PUMPS & TECHNOLOGY is active internationally and has a wide range of standard pumps and special pumps at its disposal. The portfolio ranges from small, hand-held pumps to head-high pumps for different applications and industries. Each pump is made individually to fit the requirements and needs of the customer and their place of usage.

Technologies

Our product range

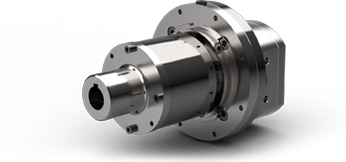

- CHEM — Stainless Steel Chemical Pumps

– Dosing Pump

– Dosing System

– Stainless Steel Gear Pump

– Pump for barrel emptying

– Submersible Pump (immersed)

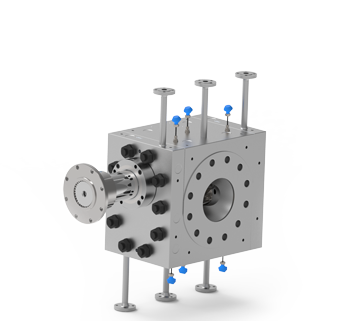

– Feed Pump 3D printer - BOOSTER — High Pressure Pump for building up pressure in the polymer process

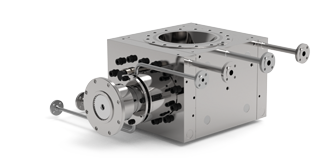

- POLY — Discharge Pump for the polymer process

- EXTRU — Melt Pump for the extrusion process

– Extrusion Pump

– Melt Pump

– Extruder Pump

Contact WITTE

Company Contact:

WITTE PUMPS & TECHNOLOGY GmbH

Lise-Meitner-Allee 20

25436 Tornesch

GERMANY

Fon: +49 04120 70659-0

Fax: +49 04120 70659-49

Mail: info(at)witte-pumps.de

Web: www.witte-pumps.com

Personal Contact:

Mr. Carsten Pump

Head of Sales & Marketing

Fon: +49 4120 70 65 9-0

Mail: sales(at)witte-pumps.de

Contact regional Sales Manager:

https://www.witte-pumps.com/sales/