If the concern is corrosion resistance when handling liquids, centrifugal pumps made of special materials are just the thing. Plastic centrifugal pumps, also called plastic pumps for short, have proven themselves especially well here. With materials such as polypropylene and PVDF, they are resistant to even aggressive acids and other chemicals.

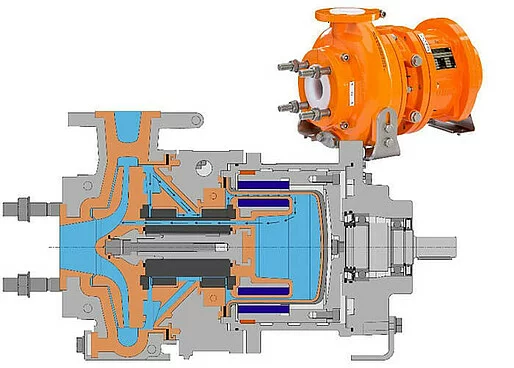

Frequently, a pump with a plastic casing is associated with the term “Plastic (centrifugal) pump.” There are such pumps, but they are most popular in the private sector for small applications – usually as cheap pond or garden pumps from home improvement stores. By contrast, industrial plastic pumps generally have robust, metallic outer casings but their interior is either lined with plastic or consists entirely of components manufactured of plastic.