Pumps & Compressors: conveying Fluids vs. conveying Gases

Pumps and Compressors function according to the same principles. However, these two kinds of machines serve different purposes. That’s why it’s worthwhile to distinguish between them precisely and to familiarize yourself with what each one can do. But what are the differences between centrifugal pumps and screw compressors, positive displacement pumps and vacuum pumps, compressors and piston pumps? Here’s an overview of the various technologies, their basic principles, and functions.

Pumps and compressors: Differences among the functions and technologies

The essential distinction between pumps and compressors is relatively easy: Pumps are machines that convey fluids. Compressors, on the other hand, are machines that convey gases.

It’s probably difficult to distinguish these concepts from one another because, strictly speaking, the designations that have sneaked into common spoken usage are not correct: For example, the bicycle pump is actually not a pump, but a piston compressor – for it conveys air into bicycle tires.

By contrast, it’s easy to explain the difference between condensers and compressors because there is none. The term “compressor” comes from the Latin “comprimere” – “to condense.” Only in slang do people talk more frequently about “compressors” when they mean small, portable electric piston compressors for generating compressed air at home. In industrial usage, the term “condenser” is more common. Technologically, however, there is no difference between these two terms.

Applications for pumps and condensers

Pumps convey fluids of all kinds. They are used for water supply and wastewater drainage, for a wide variety of production purposes and chemicals in industry, and when filling products or for other logistical processes.

Condensers are always used when compressed air is required: for example, to clean components or in pneumatic systems to control machines and systems. Compressors are also used for painting, refrigeration processes, and as energy sources to drive cylinders and turbines.

There are numerous different technologies for conveying liquids and transporting gases. That’s why it’s useful to take a closer look at the available machines and systems.

What kinds of pumps are available?

Essentially, for machines conveying fluids, a distinction is made between positive displacement pumps and centrifugal pumps. Centrifugal pumps are also called fluid flow machines, for they make use of dynamic forces to transport fluids – for a radial pump, for example, centrifugal force: A rotating wheel catches the fluid and makes it stream toward the outside.

Positive displacement pumps, by contrast, convey fluids with closed volumes. With a piston pump, this happens when a piston presses fluid into a cylinder through an inlet valve and out of the cylinder again through an outlet valve.

Both technologies, positive displacement pumps and centrifugal pumps, have been enhanced over many years and there are many different variations of the same basic principles. Would you like to learn more about these technologies and their applications? Our technology overview offers basic information about the handling principles, their intended purposes, and differences between individual technologies.

What kinds of condensers are available?

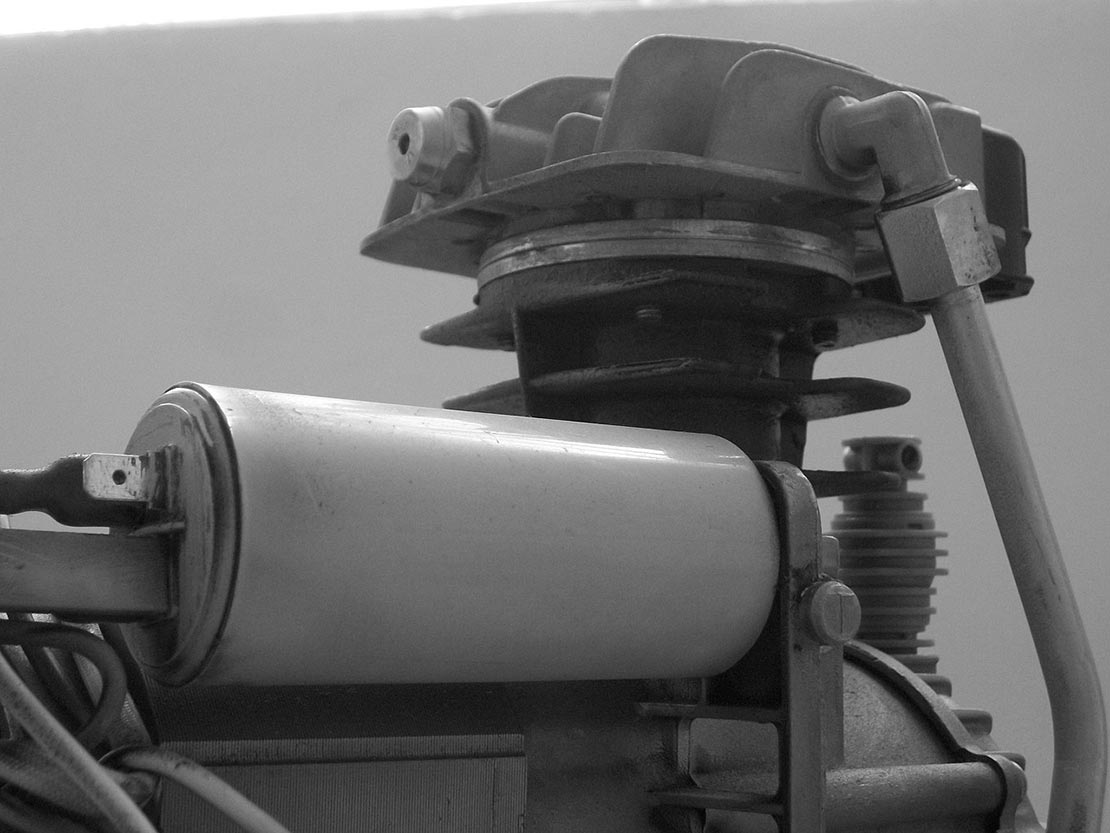

As with pumps, condensers are also classified according to essentially different operating principles: displacement condensing and dynamic condensing. The displacement condensers include piston compressors, scroll compressors, and screw compressors (also called rotation compressors). An example of this group is the bicycle air pump mentioned above. The group of dynamic condensers includes different kinds of turbocompressors.

Fundamentally, the principle of displacement condensers is similar to that of displacement pumps, however with a gas or gas mixture (air, for example) instead of a fluid: The gas is sucked into one or several chambers, the inlet is closed, and the volume of the chamber reduced – which condenses the gas. When the desired pressure is reached, a valve is opened, and the gas is released.

Dynamic condensers work with impellers that are like those of centrifugal pumps: When they are rotating, gas is accelerated between their blades. Then the gas is released, and the kinetic energy is transformed into static pressure.

Fans and blowers transport air without condensing it

While condensers transport and compress gases, fans only provide transport: They convey gas, air or other gas mixtures. But what’s the difference between a blower and a fan? There isn’t any! Both terms mean exactly the same thing. Fan – or “ventilator” – comes from the Latin “ventilare,” which means “to generate wind” – so precisely the same task that blowers perform.

Technically, with pressure of less than 1.3 bar, one speaks of fans, ventilators, or blowers; machines that generate higher pressure are called condensers. To convey gases, ventilators typically use impellers that rotate in a housing.

Fans are used for more than just creating a cool airflow. Applications include the manufacture of biogas, the ventilation of water basins in wastewater treatment, and the supply of flows in the chemical industry with process gas.

Vacuum pumps transport gases in order to generate a vacuum

Vacuum pumps have distinctive characteristics in the group of condensers – and at the same time, the term is also incorrect, strictly speaking. For although they are called pumps, they convey gas.

However, the goal is not to condense a medium, but rather to evacuate it from a working chamber in order to generate a vacuum in the chamber. As few molecules as possible should be present. This procedure is required for the production of microchips and the coating of components, for example in the production of photovoltaic systems.

There are different types and principles of vacuum pumps; these are selected depending on the desired vacuum level. The technologies include diaphragm pumps, reciprocating pumps, rotary vane pumps, and screw vacuum pumps.

For the highest form of the vacuum – the so-called ultra-high vacuum – a turbomolecular pump is required. It is switched downstream from other vacuum pumps, which generate a pre-vacuum. Without technical aids, a pressure corresponding to an ultra-high vacuum can only be achieved in outer space.

Liquid ring vacuum pumps are positive displacement pumps for gases

What are liquid ring vacuum pumps? This is another term that is easily misunderstood, since the name of these machines, which are also called liquid ring pumps for short, includes the word “liquid” but they convey and condense gases just like other vacuum pumps. However, with liquid ring vacuum pumps, the gases can include high percentages of fluids, and so be vapor-like.

The functional principle of these machines resembles the rotary vane pump, but there are a few special features. Liquids are not conveyed inside the pump; instead, the liquids serve as operating liquids.

In our description of this pump technology, we explain everything you need to know about liquid ring vacuum pumps, their applications and benefits.

Everything about pump technologies, their benefits, and applications

Now you know the basic facts about and differences between condensers and pumps. Would you like to learn more about various pump technologies? Our overview offers detailed information about many different kinds of pumps.

Do you know that your industrial process relies on state-of-the-art pump technology, but you’re unsure which kind is the right one? Our PUMPselector can help you: This free online tool enables you to quickly locate the technologies that suit your needs precisely, and you can make a non-binding inquiry. Try it out now!