About the Meaning of Efficiency in Pumps

Sustainability, decarburization, circular economy … are buzzwords of our time triggering a lot of actual projects and change in almost any industry. But let’s face it – it is not any easy task to determine the actual value of some marketing polished messages if you are not an expert yourself. What exactly does a pump manufacturer mean when talking about better efficiencies?

For decades, MUNSCH, a Germany based medium sized manufacturer of specialized chemical pumps from plastics, informs how important the development of energy efficient pumps is. Ever since the early 1990s the company invests more than average into modern technologies and ways to make its pumps more efficient and powerful.

The pump just has to keep up – nothing more.

“There have been times most customers were just happy our pump survived the conditions longer than the other one they had before” explains Frank Pauly, one of MUNSCH’s application specialists. “If corrosive fluids mix up with solids it becomes a challenge for every kind of pump and focusing on materials and shaft seals sometimes barred the view to energy consumption. However, we see an increased interest in energy efficient pumps over the last years and we are glad our enormous work finally pays off.”

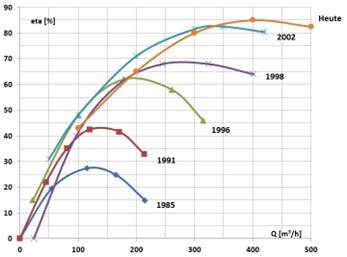

Dr. Gunther Treutz, head of hydraulic development at Munsch explains that continuous investment in new tools, new production methods, more precise machinery and top class software “increased pump efficiencies by more than 85% over the last thirty years”.

Everything has to fit in – not just efficiency

According to numbers MUNSCH is among the top in international rankings. However, in reality all things are equally important: If, for example, the pump selection has been done based on oversized process parameters it only turns out on site the pump is too large for the job. A situation pump manufacturers are used to. On short-term this creates costs for adaptions but the long-term is even more severe as “too large” often means the pumps does not operate within its optimum (refer to box. “How centrifugal pumps tick”).

Briefly Explained: How Centrifugal Pumps Tick

Centrifugal pumps have a special operating characteristic you will recognize when looking at pump curves: A specific flow pairs with just one specific pressure and one specific efficiency value. When selecting and sizing a centrifugal pump this Best Efficiency Point (BEP) is of significant importance. Aside from the lowest power requirement the BEP marks the point where wear and mechanical stress inside the pump are at the lowest. Pumps being operated around the BEP thus will last much longer.

What does a solution look like?

MUNSCH has a very strong focus on its customer industries and applications. Hence, Munsch engineers are always focused on giving expert advice including recalculations of piping plans and checks of operating concepts – always from a pump’s perspective. “This way we learn every day what operators and design engineers prefer” says Pauly. “Only by sharing information, going over P&IDs together we learn what is really required and we can instantly determine and explain the risks for the pumps involved. In most cases we are able to find very pragmatic solutions to reduce the risks for pumps at this stage of engineering. Especially in industrial environments pump solutions have to be individual and good pump selections will always need a good communication.”

But does it really matter much if a pump is just a bit more or less efficient?

Yes, it does. The majority of pumps in Industry is running continuously. With more than 8’000 hours per year and 160 million pumps, just in the European Union, there is a very long lever we have for improvements. In addition, pumps with better efficiencies running in optimal conditions will last much longer and will need less maintenance less often.

At MUNSCH the foundation is laid and the company is well prepared. “Today and in the future we focus on technologies and employees who will actively push for positive changes and better pumps. As a pump manufacturer bringing thousands of pumps into the market we feel responsible. Getting better every day is a strong motivation for us” says Stefan MUNSCH, second generation owner of the company.

In a Nutshell

Pump manufacturers can do something: With tens of thousands of new pumps leaving the factories every year it only needs a few hundred Watts in energy savings to lower the overall energy consumption significantly. But, on the customer side, just buying a new pump is not enough. Sizing and operating have to be done with care to make savings become effective. This will need the availability of expertise by manufacturers as well as the readiness of engineers and operators to share their thoughts and plans. All of this under an ever tightening frame of costs and time.

Source & Graphics: MUNSCH chemical pumps