Without a doubt, it is the best-known pump of all: the piston pump. Although their operating principle is already several hundred years old, these pumps are anything but old-timers. There are many kinds of industrial piston pumps. For industrial applications, they distinguish themselves through various characteristics – especially their suitability for conveying small flow rates at high pressure.

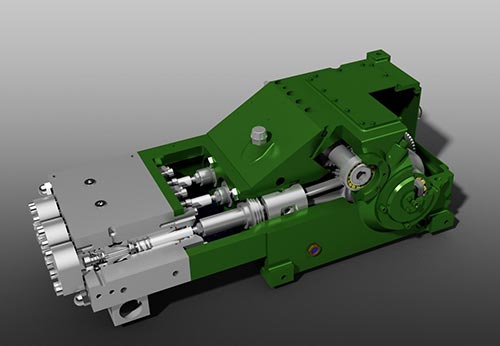

Piston Pumps

Technical Data & Characteristics:

- Delivery rate: up to 51 m³/h (225 gal/min)

- Pressure: up to 140 bar (2,030 psi)

- Temperature: 5 up to 60 °C (41 up to 140 °F)

- Viscosity: up to 50,000 mPas

- Installation: horizontal

- self-priming possible

- sealless design possible

- ATEX: ExZonen 2 & 1

- Drives: electro, diesel, hydraulic

As positive displacement pumps, piston pumps do not use centrifugal force as centrifugal pumps do; instead, they actively displace liquids – with the piston for which they are named. This piston is fed straight into a cylinder with a stroke movement; the cylinder is sealed with a valve at the inlet and outlet. During the suction phase, the piston moves out of the pump housing; in the process, the inlet valve opens and the liquid flows into the cylinder. With the conveying movement, the piston moves back into the housing; the outlet valve opens, and the medium is conveyed out of the pump.

The operating principle of piston pumps is very similar to that of plunger pumps, which is why they are often considered to be the same pump technology and confused with one another – even by pump experts. The differentiating characteristic here is the sealing: Piston pumps have an oscillating seal that moves with the piston; plunger pumps, by contrast, have a fixed seal through which the plunger moves.

What kind of piston pumps are available?

Standard piston pump models have a piston and feature a technically simple design. They are especially robust and frequently work for several decades without having to be replaced.

A disadvantage of conveying with piston pumps is the pulsation in standard models, due to the operating principle. In order to enable their use in areas where no pulsation is desired, there are several designs that work against this effect, most frequently with pulsation dampers. The pressure containers of such pumps are connected to the pump output and filled with a gas that is separated from the medium by a diaphragm. The gas acts as a cushion: During the stroke movement of the piston, fluid flows into the pressure container, the gas is compressed, and this reduces the pulsation or eliminates it entirely.

Alternatively, with appropriate capacities, triplex pumps are used. These piston pumps have three pistons that alternately pump the fluid. The multiple handling ensures even flow. Since the capacity is increased thanks to the triple effect, the size may have to be adjusted if necessary, however.

Can piston pumps be used as dosing pumps?

Like many other positive displacement pumps, piston pumps are also used as dosing pumps for liquids. They are especially suitable for the economical dosing of non-critical liquids. Here, these pumps score points with their robust design and suitability for high pressure.

Differences to piston diaphragm pumps and plunger pumps

Technically, the piston diaphragm pump and plunger pump are both related to the piston pump: Their operating principles also rely on a piston that penetrates the pump housing. With plunger pumps, this is a plunger piston that moves along the wall of the cylinder in the pump housing without a seal, sliding instead into a fixed, sealed gland.

For piston diaphragm pumps, the piston does not penetrate the cylinder filled with the liquid conveyed. Instead, a diaphragm separates the piston from the conveying chamber: The piston only penetrates an operating medium. The compression is transferred to the diaphragm so that suction and pressure impulses affect the liquid to be conveyed.

Piston pumps are not universally applicable, but rather experts in performing particular tasks: If the environment is raw or the pressure increases to the highest values, these robust machines are in their element. Depending on the design, a conveying pressure up to several thousand bar is no problem for these pumps.

Piston pumps can be used for many applications and, in addition to liquids, can also convey gases. These robust units are available in many sizes and work safely and reliably even in raw environments. In the industrial sector, these pumps are used everywhere there is high conveying pressure:

• Chemical industry

• Oil & gas

• Mining

• Energy management

• Water & wastewater treatment

• Steel & rolling mills

• Galvanizing & ceramic shops

Whether for the chemical industry, conveying and processing oil and gas or in mining and wastewater treatment: Piston pumps can do the job where other pumps fail. With sophisticated equipment for pulsation compensation and further developments such as diaphragm technology, these units that have established themselves over centuries demonstrate every day that their development is by no means at an end; instead, they can always be adapted to suit users’ requirements. As varied as the industries in which they are used, as numerous are the possible applications of piston pumps; it’s hardly possible to make a comprehensive list.

Do you think a piston pump might be the right solution for your application?

Just send us the specifications for your application and our experts will examine them to advise you further.