Every pump can handle fluids, but different applications require different technologies. Basically, the many technologies are divided into two categories of pumping principles: Centrifugal pumps convey the medium through a rotating shaft, which generate dynamic forces, and positive displacement pumps, which transport the pumped medium through self-contained volumes.

Pump Technologies

The pumped fluid is not the only deciding factor for selecting the right pump technology. The application also plays an important role:

While outlet pumps and barrel pumps are responsible for emptying containers, transfer pumps are used for transporting a medium from one location to another. They are among the pump types in the highest demand and are used most often in industry. They are also referred to as feed pumps and, depending on type and design, can transport every fluid medium in almost every desired quantity. Since many users often stipulate similar requirements, there are standards that ensure that comparable properties are offered in all manufacturers’ pumps. These pumps are referred to as standard centrifugal pump or simply standard pump.

In addition to transfer and feed pumps, circulation pumps or circulating pumps are also often in demand. They are used in cooling and heating circuits, for example, if a material has to be kept at a constant temperature with water. The circulation pump is also used frequently outside of industrial applications – it can be found in nearly every heating system or forms the heart of water treatment in swimming pool technology.

In food and beverage manufacturing and in the pharmaceutical industry, hygienic pumps are often required. With the materials that come into contact with media and design features such as easy cleaning or avoiding dead spaces, they ensure particularly hygienic handling. As a result, there is no contamination and even sensitive media, such as foods and beverages, can be transported safely. Similar requirements often apply to laboratory pumps. However, these pumps are usually much smaller than those for industrial applications.

Dosing pumps are a special type. In most cases, they also only have to process small quantities of medium. But an additional requirement calls for the highest possible throughput precision . Dosing pumps are available in numerous shapes, which differ not only with respect to precision, but also with respect to dosing intervals.

Booster pumps are used if an industrial process depends on a specific and often very high pressure. If, however, high pressure is required across the entire process (e.g., in humidification or injection molding), then high-pressure pumps are required. In contrast to this situation, media with particularly high temperatures have to be transported with high-temperature pumps that are specifically designed for this application. The same applies to pumped fluids in the extremely low temperature range; these require the use of low-temperature pumps (cryopumps).

As with the different technologies, the same also applies for design: The application stipulates the installation. While a horizontal installation may be able to simplify make for simpler maintenance, a vertical installation of the pump offers space advantages in narrow installations. Although the design of single-stage pumps is more maintenance-friendly and simpler, multi-stage pumps can build up higher pressure more easily.

Pumps that are mechanically sealed are used for many types of media and applications. If particularly aggressive, toxic or explosive fluids are handled, seal-less, hermetic pumps have to be used. There are also differences in suction characteristics: Self-priming pumps offer advantages for pumped fluids with high gas content, immersed pumps are often used in the water and wastewater sector.

Depending on pump technology and application, pump manufacturers have to ensure that various standards are being complied with. Important standards are issued, for example, by the American Petroleum Institute (API) and the International Standards Organization (ISO). The ATEX directives of the European Union for explosion protection are also relevant for numerous industries. In shipbuilding, on the other hand, special certificates of approval from a classification society such as Det Norske Veritas (DNV) are required.

The desired requirements for some applications can be fulfilled by standardized pumps. However, in some cases a standard pump is not suitable. For those purposes, well-known pump manufacturers offer custom-made designs that are specifically tailored to the medium and handling conditions. Particularly in industrial applications, most of the pumps are specifically dimensioned for the respective application since the requirements are very particular and can hardly be addressed with mass-produced standard pumps.

Most of industrial pumps today are made of cast iron, but there are also numerous special designs with respect to the material. These always depend on the medium to be handled, the technical process conditions, the industry, and also applicable standards. With pure metal pumps, the entire pump body is made of the same material, but with plastic pumps, for example, a distinction must be made between the material of the pump housing and the material of the components in contact with the medium.

Examples of common materials for components in contact with media:

- Cast iron

- Metal

- Stainless steel, nickel-chromium steel, duplex, titanium, Hastelloy, bronze

- Coated pumps with gray cast iron as the base material

- Ceramics

- PP, PFA, PVC, PVDF, PEEK, PTFE, UHMW-PE

- Synthetic carbon

Plastic pumps are often used as acid pumps or as chemical pumps or for other media that are very aggressive. Metal alloys such as Hastelloy can also be used in some cases, especially if high temperatures are achieved. Pumps whose components in contact with media are made of the relevant resistant materials, will also transport such media reliably and without additional maintenance effort.

Users in food production depend on stainless steel pumps for numerous primary processes: In contrast to a standard pump made of cast iron, they meet the industry’s high hygiene requirements. For food and pharmaceutical applications, this also applies to the pump housing: It has to be easy to clean to ensure that there will be no contamination. To meet this requirement, housings made of pure stainless steel are usually used or, optionally, coated pumps in which all pump components in contact with the medium are coated.

In the industrial sector, the electric motor has become the absolute standard for driving pumps. It offers many advantages: It operates quietly and cleanly, and electricity is usually easily available in industrial installations. When it is equipped with a frequency converter, the pump’s speed can be adapted easily to the handling requirements, thereby conserving energy and sparing wear on the installation.

Classification of electric motors

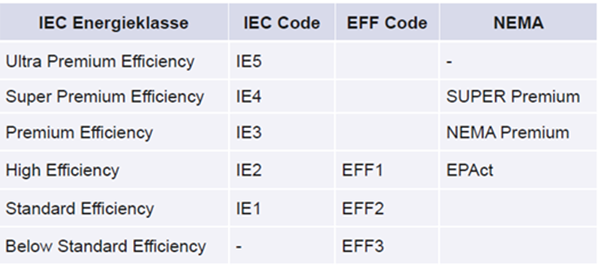

Saving energy output has long been a central issue in politics and industry. A first decisive measure in the field of energy saving was the classification of motors in the power range from 1.1 kW to 90 kW according to their efficiency (EFF code). EFF1 was considered the best, EFF3 the worst efficiency. In order to unify the different energy efficiency standards worldwide, an international standard IEC 60034-30 was created by the International Electrotechnical Commission (IEC) in 2008 and updated in 2014 (IEC 60034-30-1). This replaces the previous EFF standard and allows low-voltage asynchronous motors to be divided into efficiency classes based on their frequency, number of poles and power.

The efficiencies were standardized from IE1 as the lowest to IE5 as the currently highest achievable motor efficiency. The named efficiency describes the efficiency in converting electrical energy into mechanical energy.

The following table shows the new classification according to the IEC code in comparison to the classification according to the EFF code and the NEMA standard commonly used in the USA.

What other drives besides the electric motor are available for pumps?

- Diesel engine

- Hydraulic motor

- Compressed air

- Magnetic coupling

- Solar drive

A diesel engine may be required in remote installations that are not connected to the power grid, for example, in water works. Compared with electric motors, drives with compressed air offer a high degree of explosion protection.

If an application requires that the pumped fluid be hermetically sealed against the environment (for example, due to high flammability or in case of particularly toxic media), then magnetically coupled pumps are required: Here, the motor is connected to the impeller via a magnetic drive system so that the product chamber is safely separated from the environment.

Depending on the application case, manufacturers also offer additional special drives, for example, an environmentally friendly solar drive – entirely according to the given conditions.

The right pump for your application – discover it now!

No matter whether it is a standard application or a special case: You can find the right pump – even for the most improbable requirements. To make the right selection for your industrial application, feel free to use our free PUMPselector.

After entering your specifications, you will receive a selection of pumps suitable for your application. The more detailed and precise your information, the more precisely the PUMPselector can determine the right pump technology and then request a no-obligation quotation from the appropriate manufacturer.

This enables you to find the right pump for every requirement. If you wish, the SPA pump experts can also help you with a manual check of your data. We would also be happy to put you in contact with the appropriate manufacturer.

Or visit our SPAfair, the virtual pump fair with all the pumps of the SPA members!