FELUWA delivers the first large pump in hygienic design

Purity, cleanliness and hygiene rank first when it comes to food production. Nowadays, hygienic design is more important than ever to avoid microbiological contamination or foreign objects/particles in food. But the food market is subject to constant changes and fast-moving. Consumers prefer fresh produce which should be easy to prepare or require little or no heat treatment. In addition, the demand for products with less sugar, salt and preservatives has increased. There is an enhanced risk of a growing number of microorganisms in food enforced by these developments. This results in increasing requirements for machines in hygienic systems, such as pumps that come into direct contact with the product in food production.

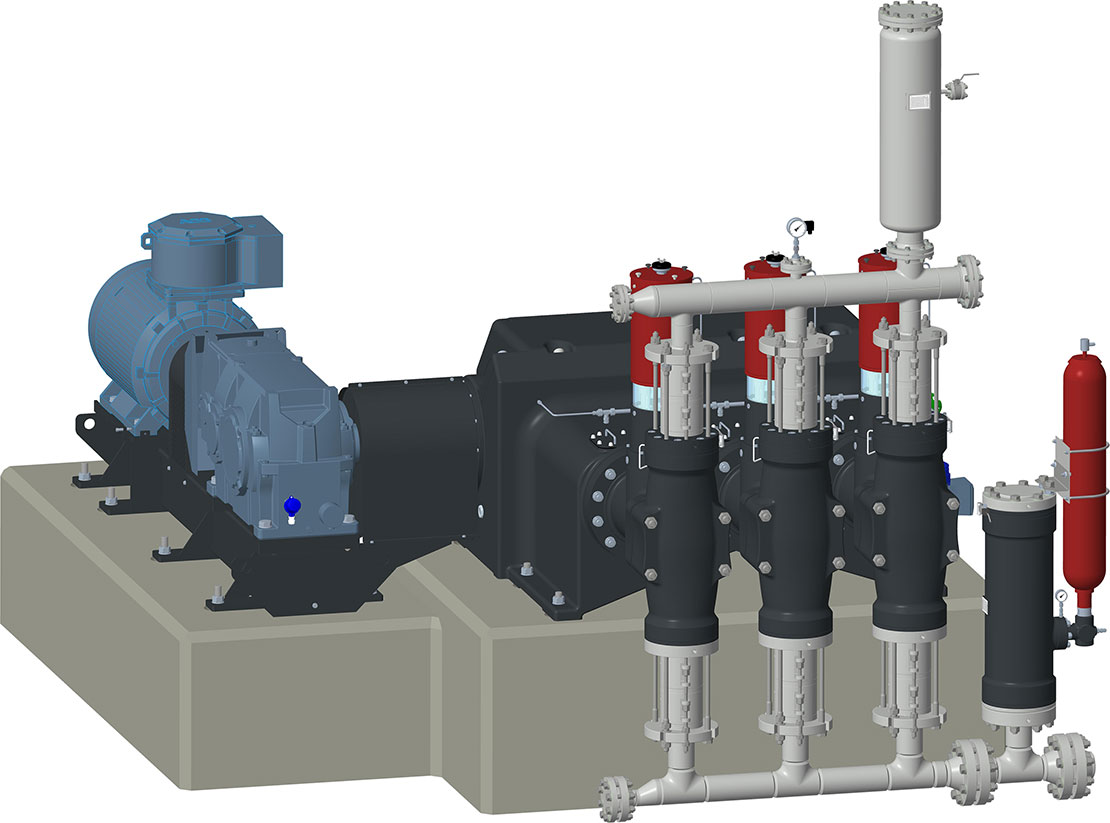

FELUWA MULTISAFE® pump in hygienic design

FELUWA recently delivered a pump in hygienic design to convey glucose solution in accordance with the EHEDG design guidelines. The TGK 300 – 3 DS 100 achieves an operating pressure of 105 bar and a flow rate of 60 m³/h.

Contamination of the pumped medium, in this case the glucose solution, would result in high costs. The product would be unusable and the worst-case scenario would be a loss of trust among customers and the closure of the plant. FELUWA MULTISAFE® pumps in hygienic design are suitable for the abrasion-free and gentle transport of food with maximum cleanability. Hence our pumps ensure safe operation in food production with reliably good quality and thus increase product safety.

Another advantage of the FELUWA MULTISAFE® pumps is the hygienic component design, as they are safe and clean due to the hermetically sealed separation of product and drive end. A pair of redundant hose-diaphragms, which are arranged one inside the other, guarantee double hermetic sealing from the drive end. The conveyed fluid will neither come in contact with the pump head nor with the hydraulic area. In the past, other manufacturers used plunger pumps to pump glucose. With this design, however, the plunger is in contact with the medium, glucose and lubricants mix and the fluid is contaminated.

The small number of medium-wetted parts and the ideally shaped pump head in terms of flow technology are characteristic advantages of the MULTISAFE® double hose diaphragm pumps. They guarantee optimum cleaning options and gentle transport.

Cleanability is crucial

In order to meet the requirements of hygienic design, all components and pipes in contact with the medium must be (self-) draining and easy to clean. Horizontal surfaces have to be avoided – they should always be designed to be slanting to one side, so that liquids can drain freely without leaving residual fluid.

In addition, the selection of fluid-contacted materials is important to ensure optimum cleanability and thus the highest level of cleanliness and biological safety. The wetted parts of the pump conveying glucose solution are made of 1.4404 with an electropolished surface. Furthermore, NBR hose-diaphragms with FDA certification are used.

The use of DownFlow valves with floating balls allows for optimum cleaning / CiP flushing without dismantling the components or manual cleaning. Additional setup and work steps are redundant, the pump can easily run completely dry by opening the flushing connection. In the process the ball drops and opens the gap between the ball and the valve seat, so that the medium behind it can also drain off. Diaphragm pumps with conventional check valves require special lifting devices to lift the valve body for emptying the pump – these can be omitted in FELUWA’s design. The hygienically designed pumps of the MULTISAFE® series also allow sterilisation with superheated steam.

EHEDG-conformity

In all areas of food and beverage, MULTISAFE® double hose-diaphragm process pumps ensure safe food production in accordance with EHEDG guidelines.

Source & Pictures: FELUWA Pumpen GmbH