The special features of the technology

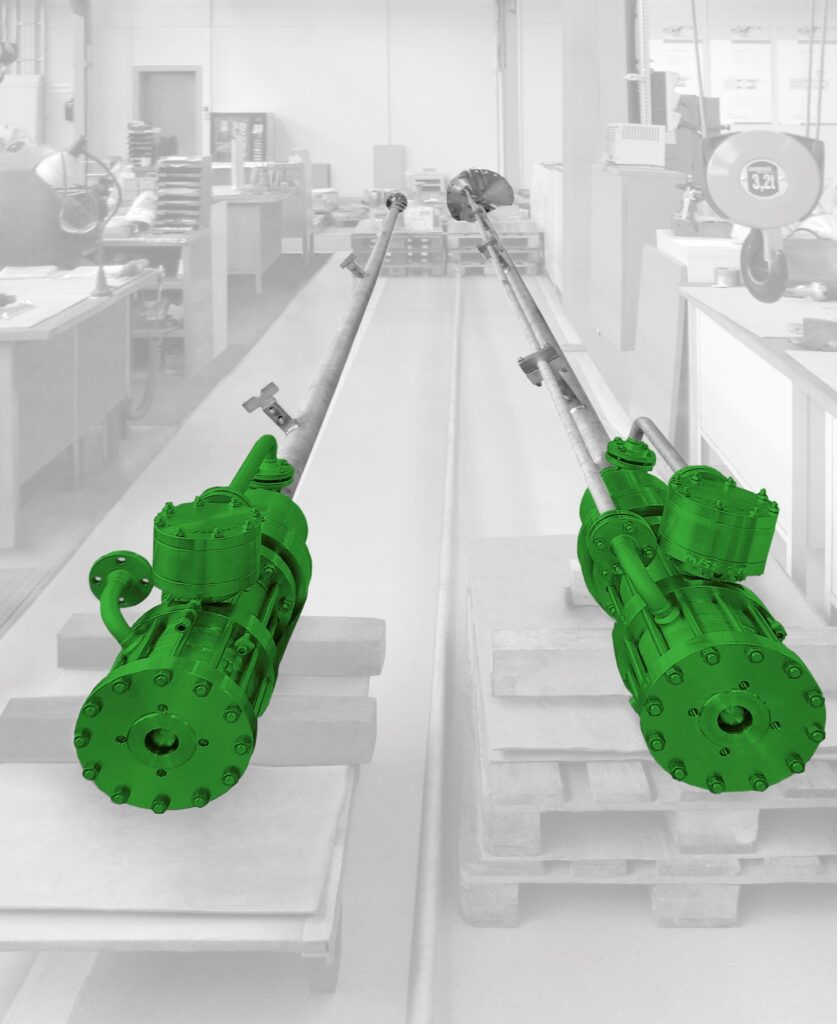

Thanks to the hermetically sealed design of the drive unit, which consists of hydraulic system and motor, it can be completely immersed in the vessel or tank. Only the discharge pipe and the electrical connection are routed through the tank cover via the manhole plate and out of the vessel. This provides the operator with significant advantages:

The fluid-lubricated slide bearings of the canned motor guide a short shaft on which the rotating parts of the motor and the hydraulic system are combined. The “ZART ®” (Zero Axial and Radial Thrust) technology from HERMETIC ensures non-contact, wear-free operation of the rotor unit. Some installations operate wear-free for many years with no maintenance requirements. Customer studies show that the MTBF times of this technology are many times longer than those of a conventional installation.

Monitoring the condition of submersible pumps is much more difficult than monitoring the condition of units that are located outside. The HERMETIC canned motor pump provides a monitoring concept that oversees the safe operation of the pump via installed sensors. In addition to operating temperature, liquid level and motor load, the specially developed MAP system can also be incorporated. This system continuously monitors the position of the rotor and is therefore a reliable indicator of unintended operating states and wear.

Canned motor pumps excel in cryogenic applications. The efficiency of electric motors decreases with rising temperatures. The canned motor is cooled and kept at a low temperature by the pumped medium, which makes it particularly efficient. Since no dynamic seals and conventional bearings are used, the hermetic pumps provide enhanced reliability and durability in this application.

In the past decades, the canned motor has proven its value as a low-maintenance, reliable drive for submersible pumps in the chemical and petrochemical industry. Equipped with state-of-the-art monitoring devices and thanks to its compact design, this technology often provides a simple, cost-effective and very reliable alternative to conventional shaft seals or magnetically coupled submersible pump versions.