Experts in the Chemical &

Petrochemical Industry

- Volute casing pumps

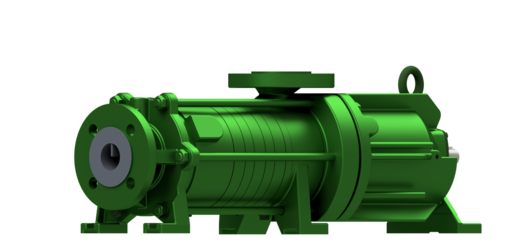

- Multistage pumps

- Side channel pumps

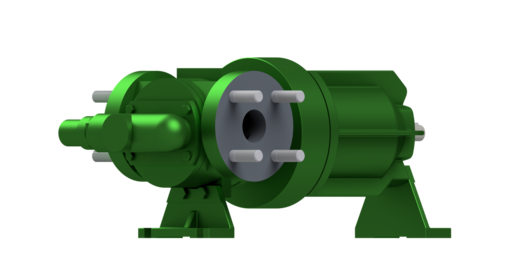

- Gear pumps

- Cat.1

since 1910

DICKOW Pumpen GmbH & Co. KG

About DICKOW

DICKOW Pumpen GmbH & Co. KG is a global and market-integrated quality manufacturer of industrial pumps. The success story as a leading supplier of high-quality special and standard pumps for chemical and petrochemical applications started in 1910. Meanwhile, DICKOW pumps can be found in plants for seawater desalination, loading and unloading of fuels and liquefied gases, chemical recycling, industrial heat transfer, airfield refueling, and oil and gas processing – and all with the quality “Made in Germany”.

Technologies

Our product range

- Centrifugal Pumps: Dickow produces centrifugal pumps suitable for handling different fluids such as liquids and liquefied gases. These pumps are available in various designs and materials to meet specific requirements.

- Magnetic Drive Pumps: Dickow specializes in magnetic drive pumps, also known as magnetically coupled pumps. These pumps feature a hermetically sealed design, eliminating the need for shaft seals, thereby preventing leakage. They are often used for handling hazardous, toxic, or expensive fluids.

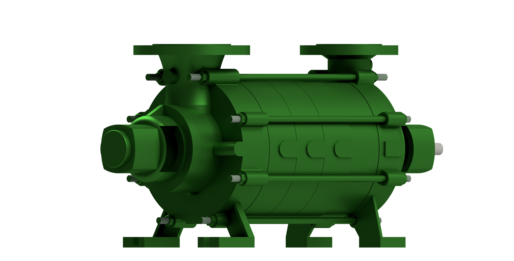

- Multistage Pumps: Dickow offers multistage pumps designed to generate higher pressure by incorporating multiple impellers. These pumps are commonly used in applications where high pressure is required, such as boiler feed, water supply, and high-pressure processes.

- Side Channel Pumps: Side channel pumps, also known as regenerative turbine pumps, are another product category offered by Dickow. These pumps are suitable for low-flow, high-pressure applications and can handle liquids with entrained gases or low lubricity.

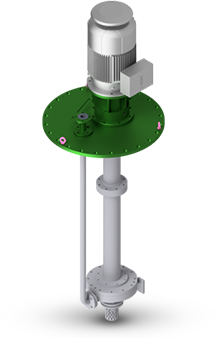

- Submersible Pumps: Dickow produces immersed pumps for applications where the pump is required to be fully submerged in the fluid being pumped. These pumps are typically used in chemical, petrochemical, and pharmaceutical industries.

- Gear Pumps: The gear pump combines the Dickow Pump magnet coupling design based on morethan 30 years experience with Tuthill GlobalGear®built on a time-tested design and more than80 years of gear pump engineering experience. The result? An unbeatable pump that offersunparalleled performance and reliability.

Contact DICKOW

Company Contact:

DICKOW Pumpen GmbH & Co. KG

Siemensstraße 22

84478 Waldkraiburg

Germany

Fon: +49 8638 602-0

Fax: +49 8638 602-200

Mail: info(at)dickow.de

Web: www.dickow.de

Personal Contact:

CHIEF SALES OFFICER

Alexander Hammer

Fon: + 49 8638 602-0

Mail: vertrieb@dickow.de

SALES MANAGER

Ralf Graef

Fon: +49 8638 602-231

Mail: graef@dickow.de