Pumps

- Digital Metering Pumps

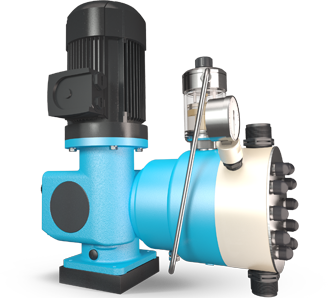

- Diaphragm Metering Pumps

- Air Operated Double Diaphragm Pumps

Systems

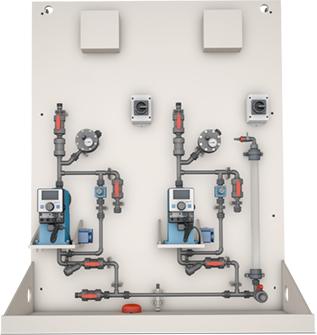

- Modular Metering Skids

- (Polymer) Preparation Systems

- Customized Systems

since 1945

sera Group Image video

About sera

The sera Group is an independent family business company group. Their core competences, dosing and compressor technology are represented by sera ProDos and sera Hydrogen (before sera ComPress). As one of the worldwide leading German manufacturers of dosing and compressor technology sera provides efficient and optimal customized solutions for all applications and has been synonymous with quality, expertise, innovation, reliability and flexibility.

With their own companies, subsidiaries in different countries and a worldwide sales and service network with more than 30 foreign representatives in over 80 countries across all continents, sera offers an optimal customer support and service locally.

Technologies

Our product range

- Dosing Pumps

(Stepper Motor Pumps) - Dosing Systems

(Polymer Preparation Stations)

Contact sera

Company Contact:

sera ProDos GmbH

sera-Straße 1

34376 Immenhausen

Germany

Fon: +49 5673 999-00

Fax: +49 5673 999-01

Mail: info(at)sera-web.com

Web: www.sera-web.com

Personal Contact:

Mr. Oliver Rund

General Manager

Fon: +49 5673 999-02

Fax: +49 5673 999-03

Mail: sales.prodos(at)sera-web.com