Are plunger pumps and piston pumps the same thing? No – although even some people who think they know pumps believe they are the same, there are differences between the two technologies. Plunger pumps are a further development of the piston pump. How exactly does this technology work and what are its special features? Here’s an overview of all details of plunger pumps.

Plunger Pumps

Technical Data & Characteristics:

- Delivery rate: up to 4,000 l/min (1,056 gal/min)

- Delivery head: up to 35,000 m (114,829 ft)

- Pressure: up to 3,500 bar (50,763 psi)

- Inlet pressure/ Suction pressure: atmospheric up to 1000 bar (14,504 psi)

- Temperature: up 200 °C (392 °F)

- Viscosity: up to 2000 mPas

- pH-value: 2 – 12

- Solids: up to 80 % (max. 0.35 mm)

- Installations: horizontal, vertical

- Submersibility: submerged (only for deep sea applications)

- API 674 standard

- ATEX/Ex Protection: Zone 2 & 1

- Drives: electro, diesel, hydraulic, compressed air

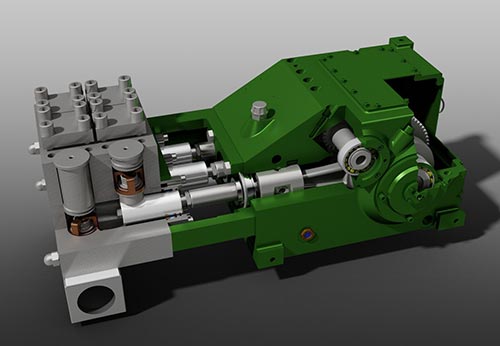

In principle, a plunger pump works like a piston pump, and is thus one of the oscillating positive displacement pumps. However, instead of a piston, these pumps have one or several plungers as displacing element(s). The plunger is fed straight into a working chamber by a stroke movement, whereby the plunger is sealed off by a fixed seal. In piston pumps, on the other hand, the seal oscillates together with the displacing element (piston).

During intake, the plunger moves out of the working chamber, generating a suction effect, as the liquid to be conveyed streams into the pump through a suction valve. With the conveying movement, the plunger moves back, and the suction valve closes due to its own weight, a pressure valve opens, and the medium is conveyed out of the pump by the plunger.

Plunger pumps are flexible workhorses: They can adapt to the handling of nearly any liquid, they convey large quantities even with high operating pressure, and they have a linear characteristic curve. With their high efficiency and correspondingly low energy consumption, they also offer an ecologically sensible option for many applications.

Plunger pumps are suitable, practically even predestined, for high pressures. In contrast to piston pumps, these flexible high-pressure pumps can also generate high flow rates. Thanks to their dynamic high-pressure seal, they come in many different variants, which are adapted to a broad bandwidth of liquids and environmental conditions. This allows them to safely convey even abrasive, corrosive, hot, cold, viscous, toxic, and flammable liquids at high pressures.

With these properties, plunger pumps are used in those industries that make high demands on handling technology and for situations where many other pump technologies are not suitable, especially in hydraulic applications. Among others, these include the following industries:

• Chemistry

• Oil & gas

• Mining

• Drilling technology & fracking

• Water grouting & water hydraulics

• High-pressure cleaning & water jet cutting

Due to their enormously wide application field, plunger pumps are therefore offered in numerous variants and sizes. As high-pressure pumps, they are in a position to create operating pressures of several thousand bar, usually with comparably low capacities.

Plunger pump sizes range from just 15 kW output to models with an output of 1,500 kW. The smallest models are used to remove rust and paint or to clean small surfaces. The largest plunger pump models are used in large systems in the oil and gas industry, in steel mills or in mining.

Plunger pumps for dosing liquids

Since plunger pumps are among the oscillating displacement pumps, their capacity depends only on the speed of the camshaft. Their characteristic curve is nearly linear and behaves directly proportionally to the drive speed. This means that dosing tasks can be performed with plunger pumps, as can speed-dependent pressure regulation.

The broad spectrum of sizes and variants of plunger pumps can make selecting the right model difficult.

We’ll be glad to check their suitability for your application. Just send us your non-binding inquiry for a detailed review.