The liquid ring vacuum pump consists of a cylindrical housing and a star-shaped, eccentrically arranged impeller. The pump’s working space is frequently filled with operating liquid during operation, normally with water. When the impeller turns, the liquid forms a liquid ring that seals the impeller channels even though these do not touch the housing. The eccentrically arranged blades penetrate at different depths into the liquid ring. This ring then works like a piston, by alternately sucking in and compressing the gas.

In addition to acting as a seal, the liquid ring also takes over the compression function. Furthermore, it can be used to cool and condense the conveyed gas. The condensing increases the suction power of the liquid ring vacuum pump.

Thanks to a flexible pressure slot in the control disk, the liquid ring vacuum pump works with maximum efficiency across the entire suction range. The pressure slit opening created this way adjusts to the existing pressure relations so that there is no excessive compression of the conveyed gases.

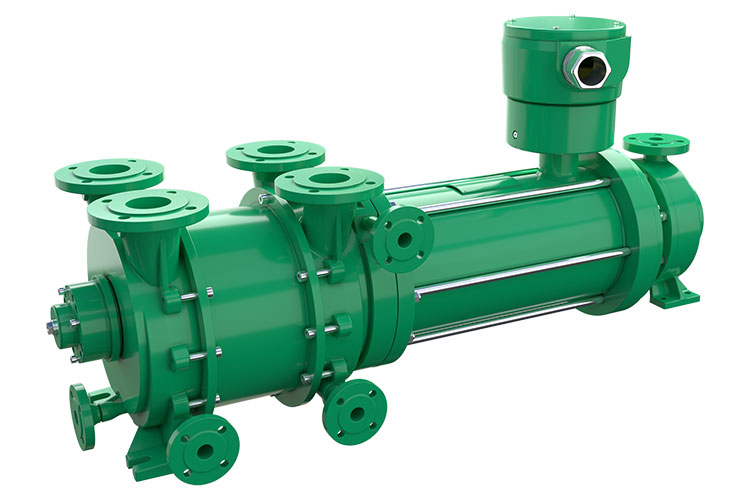

Depending on the size, single-stage displacement pumps are equipped with single or double-bladed impellers. The special features here are that the pumps do not need to be lubricated and there are no components touching each other in the conveying chamber. This is why these pumps distinguish themselves with their quiet, low-vibration operation and their simple, robust construction.

The operating principle of a liquid ring pump is similar to that of a rotary vane pump. Instead of fixed blades, however, the rotary vane pump has vanes that are also sealed off from the housing by a liquid ring.