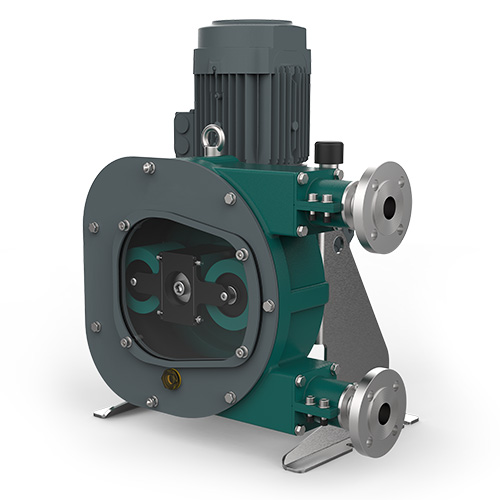

Hose pumps, also known as peristaltic pumps, convey many liquids with an exceptional technology. These robust pumps can be used for conveying as well as for dosing. And these units from the group of positive displacement pumps have some benefits to offer.

Hose Pumps

Technical Data & Characteristics:

- Delivery rate: up to 15 m³/h (66 gal/min)

- Delivery head: up to 100 m (328 ft)

- Pressure: up to 10 bar (145 psi)

- Viscosities: up to 50,000 mm²/sec

- Temperatures: 0 °C up to 80 °C (32 – 176 °F)

- pH-value: 0 – 14

- Gases: up to 99 %

- Solids: up to 80 % (max. 45 mm)

- Installations: horizontal, vertical

- self-priming possible

- sealless design possible

- ATEX: Ex Zones 2 & 1

- ISO, EN standard

- hygienic design possible

- Drives: electro, hydraulic

Inside the hose pump, there is a hose, which is fed in a U-shape through the housing. To convey liquid, the pump hose is clamped by rollers, which turn on a rotor: The rotor’s movement causes the clamped point to move along the hose. The medium inside is thus conveyed through the inside of the pump hose from the intake side to the pressure side. So hose pumps belong to the positive displacement pumps.

Hose pumps are sometimes also called peristaltic pumps or squeeze pumps. The term “peristaltic” comes from the Greek peri = “around” and stellein = “to put in motion” and refers to the muscles of organs such as the esophagus, which also conveys a medium by contraction.

A rotor, a hose and a housing: Hardly anything else is necessary for the simple, persuasive technology of the hose pump. Thanks to its simple design, great flexibility, and easy maintenance, this pump technology is first choice for conveying many different kinds of media in numerous industries.

The conveyor hoses of peristaltic pumps can be adapted for many kinds of media. With correct selection of the hose material, peristaltic pumps can be operated continuously. For this, the pump hose must be appropriate for the characteristics of the conveyed liquid and the other circumstances of the desired application. Maintenance is only required when the hose needs to be replaced after longer downtimes. Since the pump hose is often made of commonly available materials, replacement costs are very low.

Peristaltic pumps’ great dosing precision reduces operators’ costs for consumables, since the pump doses exactly as much fluid handled as required. In contrast to other dosing pumps, peristaltic pumps convey evenly and with little pulsation, which can significantly increase the quality of the process and of the final product. Even for small quantities, peristaltic pumps enable precise, even dosing with great repeatability. They also run dry and require only minor maintenance effort.

Exchangeable pump heads create flexibility

If a peristaltic pump’s hose must be replaced due to material fatigue, the maintenance effort required is very low: Manufacturers of high-quality peristaltic pumps enable replacement by changing the pump head. It contains the hose and the conveyor rollers, and sometimes even integrated leakage detection. Since the operating personnel can replace the entire head, it does not come into contact with the liquid conveyed. Furthermore, maintenance requires no tools.

By exchanging the pump head, the hose pump can also be adapted easily to the particularities of the fluid handled: If a different medium should be transported, it’s sufficient to select a pump head whose hose is made from a suitable material. The other components of the pump can still be used without any adaptation.

Hose pumps come in numerous sizes, covering a broad range of applications: from pure dosing pumps for capacities from 0.1 to 2,000 ml/min to feed pumps for quantities from 10 to several 10,000 l/h, to large industrial pumps with capacities of up to 100,000 l/hour. The components of high-quality hose pumps can withstand an operating pressure of up to 16 bar.

With their flexible hose materials and wide spectrum of capacities, peristaltic pumps are suitable for use in many industries. These include:

- Chemical industry

- Mining

- Water & Wastewater

- Food & Pharmacy

Peristaltic pumps as dosing pumpsPeristaltic pump technology offers many benefits, which also apply when dosing liquids. Especially for continuous dosing tasks, for example in wastewater treatment or various areas of the process industry, these robust pumps stand the test thanks to their easy and reliable operation.

Due to their displacement handling principle, peristaltic pumps can also convey high-viscosity media. In high-quality units, the closed system of these run-dry pumps has surfaces that can be cleaned and sterilized easily. That’s why peristaltic pumps are also suitable for conveying and dosing in pharmaceutical and food production.

In contrast to some other pump technologies, but for the hose, the fluid handled is hermetically separated from lubricants and all other components of the pump: The hose is the only part of the pump in contact with media. And because it runs dry and has no valves, conveying is especially hygienic.

Handling of sensitive media entirely without shear forces

Since there are conveying chambers (so-called cavities) between the individual rollers that clamp the pump hose, there are almost no shear forces on the liquid to be conveyed. Thanks to this special feature, hose pumps are especially well-suited for the transport of shear-sensitive media such as yogurt containing pieces of fruit, or other liquids with solid content. Similarly, the displacement conveying of hose pumps enables the transport of high-viscosity fluids. Even conveying also has a positive effect on the medium and the connected systems in that cavitation is avoided almost completely.

Whether conveying or dosing: We’ll help you select the right hose pump for your application! Send your non-binding inquiry and the specialized manufacturer from the Star Pump Alliance will make you an offer that will suit your requirements precisely.