“Showing teeth” when pumping low- to high-viscosity fluids: Gear pumps are very flexible when it comes to the uniform supply of media. They are especially preferred in hydraulics, for they work without pulsation and are low-maintenance. In addition to hydraulic motors, typical areas of application include the handling of solvents, molten plastics, rubber, chemicals, barrier media for mechanical seals, oils, fuels and additives, but they are also well-suited for dosing.

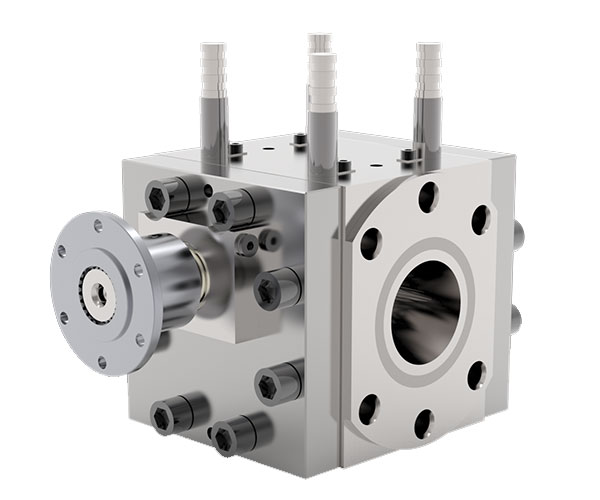

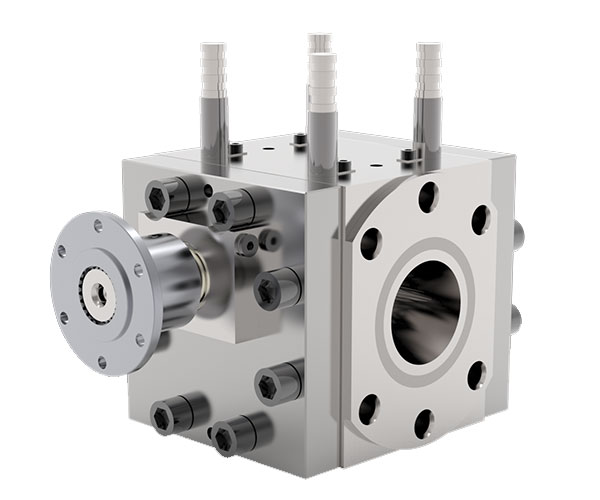

Gear Pumps

Technical Data & Characteristics:

- Delivery rate: 0.4 to 45 m³/h (1.8 to 198 gpm)

- Delivery head: 5 to 135 m (16.4 to 443 ft)

- Pressure: up to 25 bar (362 psi)

- Viscosity: up to 10,000 mPas

- Temperature: -120 °C up to +300 °C (-184 °F up to +572 °F)

- pH-value: 0 – 14

- Solids: max. 1 % (max. 6 mm)

- Installation: horizontal

- self-priming possible

- sealless

- ATEX (Ex Zone 1 & 2)

- Drives: electro, hydraulic

In addition to the housing with inlet and outlet, the gear pump consists of two gears, one of which is driven. Here, a conveying chamber is created between two gears. In it, the gear teeth, which interlock with one another, move the conveying fluid to the housing wall along the suction and pressure side. If two gear teeth meet, the play between the teeth is very tight – so the conveying fluid is pressed out of the gear gap. Gear pumps are therefore displacement pumps.

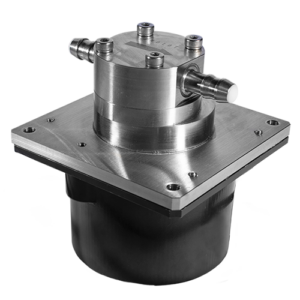

Internal gear pumps are a special case: Here the medium is conveyed by just one gear, which runs eccentrically in the internal interlocking of a gear ring.

Gear pumps are used frequently in hydraulics. For even if there is pressure, the hydraulic gear pump generates a practically continuous volume flow. Resistance from output, throttle points or switch elements do not affect the operation. Pumps for hydraulic motors are operated with hydraulic fluid. They come in numerous sizes for all conceivable uses.

Industrial pumps are typically used to convey chemicals, and in the manufacturing and processing of plastics, as extrusion pumps and polymer pumps, and also as booster pumps and dosing pumps as well as for loading sealing pressure systems, lubricating gears or compressors, for transfer tasks in tank systems, exhaust gas cleaning, color printing, 3D printing, 2-component gluing or loading hardening ovens with methanol. They are also used in the food or feed industry. Here, they can handle low and high-viscosity media, which is an advantage in applications where the viscosity of various conveyed fluids is quite varied or different media have to be conveyed with only one pump. The viscosity may be between 0.2 mPa and 40 million mPa for conveyance.

The individual media that can be conveyed with gear pumps include, among others:

- Chemical industry: alcohols, additives, bitumen, tars, wax, acids and bases, esters, glycerin, resins, isocyanate, adhesives, monomers, oils, and phenols

- Polymer manufacturing and processing: PET, PBT, PS, ABS, PVC, PE, PEEK, cellulose, nylon, and other polymers

- Food / feed processing: plant oils, butter and margarine, flavorings, chocolate, licorice, chewing gum mass, syrup, honey, gelatins, mustard and ketchup, sugar solutions, enzymes

- Pharmacy: amino acids, lotion, shampoo, vitamins

Gear pumps are not suitable for handling media with solid content larger than 50 μm (= 0.05 mm) since it can damage or block the individual gear teeth. To prevent any tooth gap here, operators should use other pump technologies for such applications or a suitable coarse filter in front of the pump.

Flexibility with regard to the viscosity of the medium is not the only benefit that distinguishes gear pumps. Other benefits include:

Flexibility with regard to the viscosity of the medium is not the only benefit that distinguishes gear pumps. Other benefits include:

- High reliability

- Hreat dosing precision

- High volumetric efficiency

- Low-pulsation conveyance

- High pre-pressures possible

- High differential pressures in small installation space

- High availability

- Low life cycle costs

- Low maintenance effort

- Simple construction / easy repair

- Suitable for lubricating media

- Good to very good chemical resistance

- different viscosities can be covered with just one pump

- absolute freedom from leakage with hermetically sealed pumps

Gear pumps come in many different sizes. They thus cover a broad performance spectrum: Pump capacities of almost 0 l/min up to 200 m³/h are possible. Some of them also enables a differential pressure up to 550 bar and system pressure up to 700 bar. Appropriate gear pumps are also available for areas subject to explosion hazards.

Due to their volumetric handling principle, gear pumps can determine the quantity of conveyed medium very precisely. That’s why gear pumps are also used as dosing pumps. And there are many different sizes available for dosing, so that there are many possible areas of application.

To make the selection of the right system easier for users and enable quick start-up, some suppliers offer complete dosing systems that are based on a gear pump. These systems already have containers, a scale, and a weighing platform or with control and regulation technology and sometimes even an integrated CAN connection. This way, both volumetric and gravimetric dosing are possible.

Whether for high viscosities, for dosing or other applications with accuracy in all industries: With their great flexibility and easy maintenance, gear pumps are very popular and therefore used in many industries.

Do gear pumps seem ideal for your application and are you convinced of their benefits? We’ll be glad to check your non-binding inquiry!