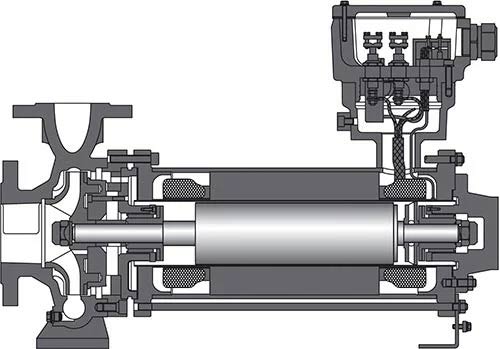

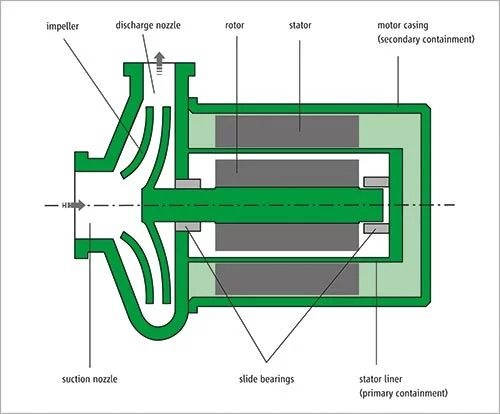

The focus of the canned motor pump is on the motor: In contrast to normal centrifugal pumps, the rotating part of the motor is on the same shaft as the pump’s hydraulics. This rotor is completely surrounded by a hermetically sealed can, which separates the rotor space from the stator of the canned motor. Since the motor is an integral part of the pump, canned motor pumps are very quiet.

In addition to the sealed can, the pressure-proof motor casing represents a second safety sleeve. Even if the fluid handled escapes from the can in case of disaster, it is prevented safely from escaping uncontrolled into the environment. Thanks to this clever design, shaft seals such as the normal mechanical seal are superfluous and there can be no leaks: The shaft seal-free canned motor pump handles fluids and fluid gases hermetically. An alternative drive possibility is magnetic couplings, which also preserve the safe, seal-free properties of this pump.

The rotor is guided by two hydrodynamic bearings, which are lubricated by the fluid handled and lift the rotor touch-free in operation. With some units, the axial forces are neutralized by a thrust balance, so that the entire rotor runs touch-free and thus also wear-free. This way, the service lives are increased, and life-cycle costs reduced.

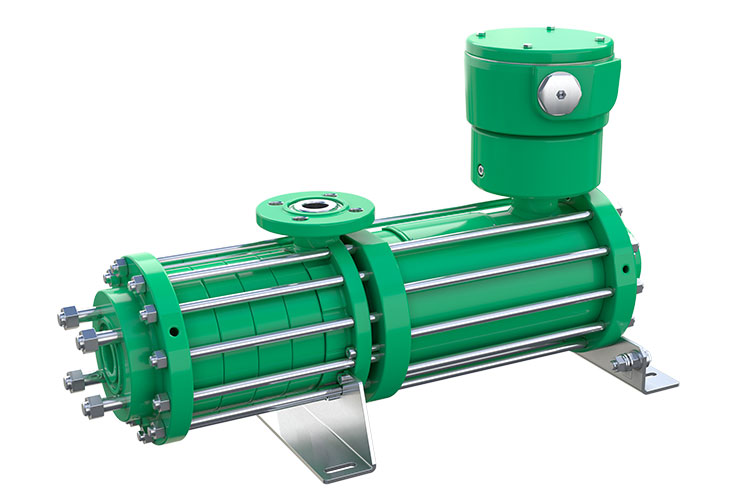

Due to their design, canned motor pumps enable higher flow rates, heads, and pressures as compared to other centrifugal pumps. Their temperature sensitivity is also much greater, which also enables special applications in the high- or low-temperature ranges. Furthermore, the possible viscosity of the fluid handled is comparatively high for centrifugal pumps.