Efficient and safe filling of spray cans

Spray cans are metal containers, containing liquid under pressure, so that it can be sprayed. They are pressurized, whereas aerosols mainly propane-butane-mixtures are used.

Spray cans are mainly produced in the cosmetic as well as in paint and coating industry.

Solution

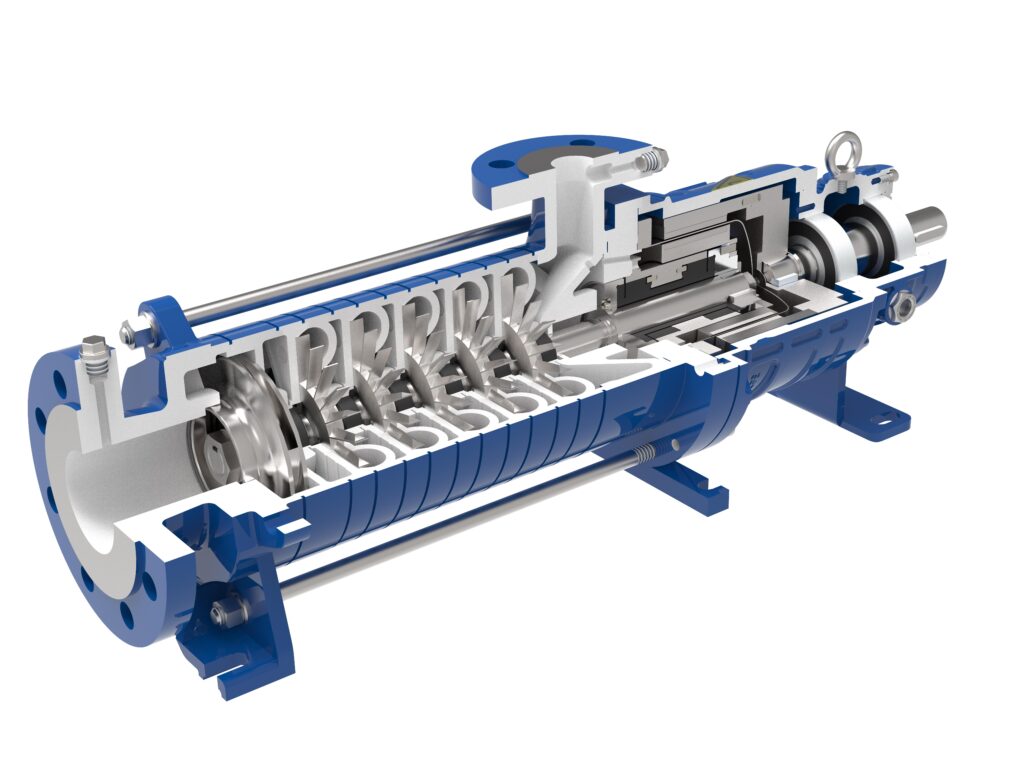

Its self-priming ability and low NPSH value allows the Side Channel Pump to be placed beside the tank. This location reduces the investment and constructional expenditures.The ability of the Side Channel Pump to handle liquids with gas entrainments of up to 50 % is of great advantage, particularly at increased ambient temperatures and in the case of solar heating of tank and pipings. There is no risk of flow interruption caused by gas bubbles within the pipelines.